What Are the Innovations in Coffee Packaging?

Meta Description:

Learn about the latest innovations in coffee packaging, focusing on the significance of empty Nespresso capsule making machines. Explore technological advancements, sustainability efforts, and future trends shaping the coffee industry.

Introduction

The coffee industry has witnessed remarkable growth over the past few decades, with Nespresso machines becoming a household staple for many coffee enthusiasts. These sleek, convenient devices have revolutionized the way we enjoy coffee, offering a variety of blends and flavors at the push of a button. However, behind this convenience lies a complex process of coffee packaging, particularly in the creation and use of Nespresso capsules. Empty Nespresso capsule making machines have emerged as a critical innovation in this domain, enabling efficient, high-quality, and sustainable coffee packaging solutions.

The Basics of Empty Nespresso Capsule-Making Machines

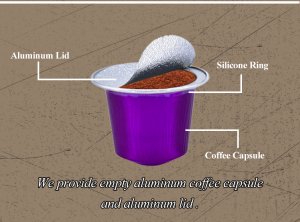

Empty Nespresso capsule making machines are specialized devices designed to manufacture the small, single-use capsules that are compatible with Nespresso coffee machines. These machines primarily function to form, fill, and seal the capsules with precision. The process involves molding the capsule’s body, filling it with the exact amount of ground coffee, and sealing it to maintain freshness and flavor.

There are various types of capsule making machines available on the market, each catering to different production capacities and technological needs. These range from small, semi-automatic machines suitable for small coffee shops or startups, to fully automated industrial-scale machines designed for large coffee manufacturers. The choice of machine often depends on the volume of production and the specific requirements of the coffee brand.

Technological Advancements in Capsule Manufacturing

Technological advancements have significantly enhanced the capabilities of capsule making machines. Modern machines are equipped with sophisticated features that ensure precision, efficiency, and consistency in capsule production. For instance, advanced sensors and automated control systems help maintain exact measurements of coffee filling and sealing, reducing waste and ensuring uniformity.

One notable innovation is the integration of IoT (Internet of Things) technology, allowing real-time monitoring and control of the manufacturing process. This connectivity enables manufacturers to track performance, identify issues promptly, and make data-driven decisions to optimize production. Additionally, improvements in machine design and materials have led to faster production speeds and reduced maintenance requirements.

AI and machine learning algorithms are also making their way into capsule production. These technologies can predict maintenance needs, optimize production schedules, and improve the overall efficiency of the manufacturing process. With such advancements, the industry can ensure that each capsule produced is of the highest quality, consistently meeting consumer expectations.

Why is consistency crucial in the production of coffee capsules?

Consistency and quality are paramount in the production of Nespresso capsules. Consumers expect each capsule to deliver the same rich flavor and aroma, regardless of when or where it was made. To achieve this, manufacturers employ rigorous quality control measures throughout the production process.

Modern capsule making machines are equipped with quality assurance features such as automated inspection systems that detect defects in capsule formation, filling, and sealing. These systems use advanced imaging and laser technologies to ensure that each capsule meets stringent quality standards. Moreover, the use of standardized materials and processes helps maintain uniformity across batches, providing consumers with a reliable coffee experience.

Additionally, the integration of blockchain technology in the production process is emerging as a means to ensure traceability and transparency. This technology allows manufacturers to track each step of the production process, ensuring that all quality control measures are strictly followed. It also provides consumers with the assurance that the capsules they purchase meet the highest standards of quality and safety.

What materials are used for making capsules, and how do they impact the environment?

The choice of materials used in Nespresso capsules has significant implications for both product quality and environmental impact. Traditionally, capsules have been made from aluminum or plastic, which pose challenges in terms of sustainability and recyclability. However, recent innovations have led to the development of more eco-friendly alternatives.

Biodegradable and compostable capsules have emerged as a promising solution to the environmental concerns associated with single-use coffee pods. These capsules are made from plant-based materials or other sustainable sources, which decompose naturally and reduce landfill waste. The adoption of such materials not only aligns with the growing consumer demand for sustainable products but also positions coffee brands as environmentally responsible.

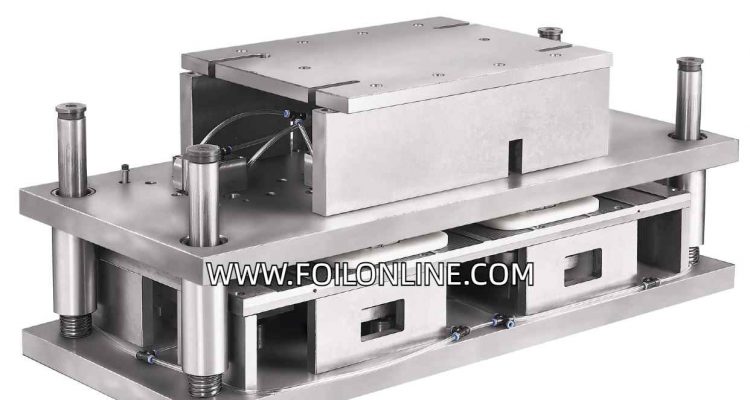

Aluminum Nespresso Capsules Cup Forming Making Machine

Another innovative approach involves the use of recycled materials in capsule production. By incorporating recycled aluminum or plastic, manufacturers can reduce their reliance on virgin materials and decrease their overall environmental footprint. These efforts are part of a broader commitment to sustainability, ensuring that the coffee industry can meet consumer demand without compromising the health of the planet.

Economic Impact of Adopting Capsule Making Machines

For coffee companies, the decision to adopt in-house capsule making machines involves a careful analysis of costs and benefits. While the initial investment in machinery can be substantial, the long-term economic advantages often justify the expenditure.

In-house capsule production allows companies to have greater control over the quality and supply of their products. It also reduces reliance on third-party suppliers, which can lead to cost savings and increased operational efficiency. Moreover, the ability to produce custom capsules tailored to specific blends and flavors enhances brand differentiation and customer loyalty.

By manufacturing capsules in-house, companies can also respond more swiftly to market changes and consumer preferences, ensuring they stay competitive in a dynamic industry. Additionally, the potential for reducing waste and improving sustainability through advanced manufacturing techniques can result in further cost savings and positive brand image.

The economic impact extends beyond direct cost savings. In-house production capabilities allow companies to innovate more freely, experimenting with new blends, capsule designs, and packaging solutions. This flexibility can lead to the development of unique products that capture the interest of consumers and drive market growth.

What are the Sustainability and Environmental Considerations

The environmental impact of single-use coffee capsules has been a significant concern for both consumers and manufacturers. Traditional plastic and aluminum capsules contribute to landfill waste and environmental pollution, prompting a need for more sustainable solutions.

Modern capsule making machines are addressing these challenges by incorporating sustainable practices and materials. The shift towards biodegradable and compostable capsules is a key development, as these alternatives help reduce the environmental footprint of coffee consumption. Furthermore, advancements in recycling technologies are enabling the recovery and reuse of materials from used capsules, promoting a circular economy.

Manufacturers are also exploring ways to minimize energy consumption and waste during the production process. For instance, machines with energy-efficient designs and automated systems that reduce material waste contribute to more sustainable manufacturing practices. Renewable energy sources, such as solar and wind power, are also being integrated into production facilities to reduce environmental impact.

Future Trends in Capsule Manufacturing

The future of capsule manufacturing is poised for exciting developments, driven by technological innovation and evolving consumer demands. One anticipated trend is the increased adoption of smart manufacturing technologies, including AI and machine learning, to enhance production efficiency and product quality.

Another trend is the continued focus on sustainability, with ongoing research into new materials and recycling methods. The development of fully compostable capsules that can decompose within a short period is a key area of interest, as it addresses both environmental and consumer concerns.

Additionally, personalized coffee experiences are likely to become more prevalent, with capsule making machines enabling the customization of blends and flavors to meet individual preferences. This trend aligns with the broader movement towards personalized consumer products and services.

The integration of augmented reality (AR) and virtual reality (VR) technologies could also revolutionize the consumer experience. Imagine being able to visualize the entire journey of your coffee capsule, from production to consumption, through an AR app. This level of transparency and engagement could enhance brand loyalty and deepen the connection between consumers and their favorite coffee brands.

Conclusion

Empty Nespresso capsule making machines play a crucial role in the innovations shaping the coffee packaging industry. These machines enable precise, efficient, and high-quality production of coffee capsules, meeting the demands of both manufacturers and consumers. As technological advancements continue to drive improvements in manufacturing processes, and as sustainability becomes an increasingly important consideration, the future of capsule manufacturing looks promising. Embracing these innovations not only enhances the coffee experience but also promotes environmental responsibility, ensuring that the industry can thrive sustainably in the years to come.

In short, the evolution of empty Nespresso capsule making machines reflects the broader trends of technological progress and sustainability in the coffee industry. By leveraging these innovations, coffee companies can deliver exceptional products while minimizing their environmental impact, ultimately contributing to a more sustainable future for coffee lovers worldwide. The ongoing commitment to innovation and environmental stewardship will be essential in navigating the challenges and opportunities that lie ahead in the dynamic world of coffee packaging.

Call to Action

Ready to elevate your coffee production with cutting-edge capsule making technology? Explore the latest in aluminum Nespresso capsule making machines at FoilOnline. Discover how these advanced machines can enhance your efficiency, ensure high-quality output, and support sustainable practices. Visit now and take the first step towards innovation in coffee packaging.