The Advantage of Versatile Shapes in Aluminum Foil-Making Machines

Introduction

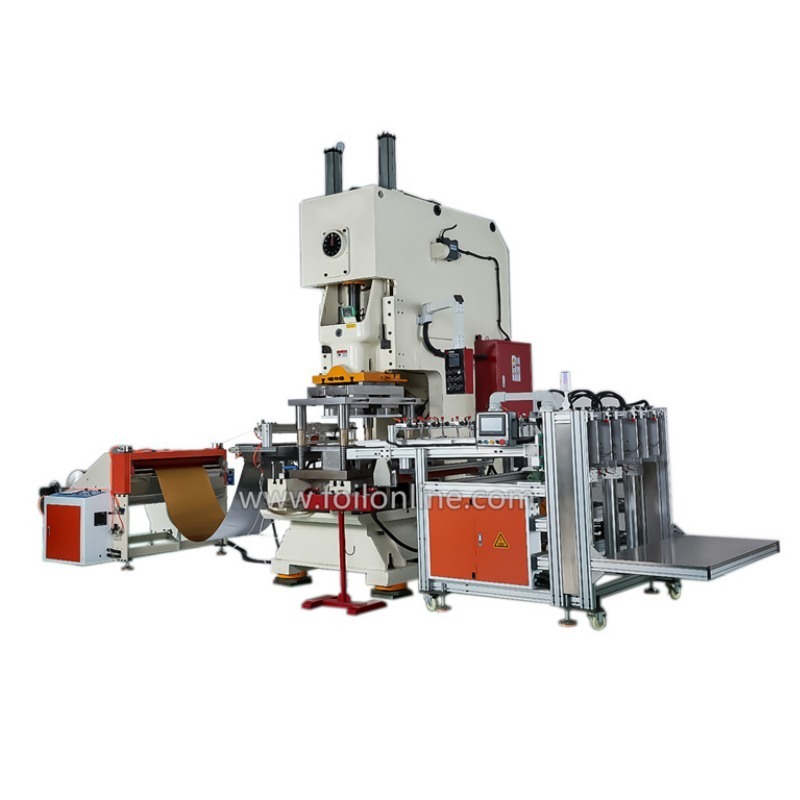

However, in the food industry, aluminum foil-making machines play a huge role too in food packaging, catering, and retail. It makes this machinery shape the aluminum foil into trays of all sizes, further helping the business pack and store food safely and efficiently. These machines are so important because they are capable of making versatile shapes.

As a result, manufacturers may provide trays in several designs, including circular, square, and rectangular shapes and custom shapes for objects with specific requirements.

These machines are especially versatile in today’s market as most businesses are required to accommodate different food types and consumer preferences and pack various packaging sizes and varieties.

Whether the purpose is to preserve food, transport goods with certainty, or simply because they look appealing, custom-shaped aluminum foil trays are becoming the most important element in improving production and saving costs. In this post, we will delve into how these machines are reshaping the way we think about packaging.

Why Are Versatile Shapes Important in Aluminum Foil-Making Machines?

Aluminum is often used to make foil for tray-making machines because it has versatile shapes that form the basis of manufacturing diverse trays for different uses. All types of food, from baked goods to ready-to-eat meals, require custom packaging in today’s market. This allows businesses to create different shapes, like round, square, or rectangular, to accommodate a particular design or even custom designs in order to meet a specific customer need.

For example, in the food business, you will need trays that fit into ovens, microwaves, or delivery boxes. Of course, cakes or pies may be baked in round trays, whereas sandwiches or salads might need rectangular or square trays. All these shapes are produced in versatile machines using the same equipment. Businesses save money by not having to purchase several machines for different shapes.

Versatile shapes are important for another reason: one can make the food look more appealing. A specially shaped tray can serve to make a dish stand out on a shelf or in a store display, for example. It will also help you attract more customers. The design flexibility also allows for trays to be made for particular food packaging requirements, such as a stacking tray for easy transport and a tray having compartments to protect different food items from each other.

In short, aluminum foil-making machines are an answer to versatile shapes that allow businesses to make packaging for many different products, tapping lower stocks and aligning with the current pockets of the consumers.

How Do Versatile Shapes Improve Efficiency in Production?

Not only are businesses able to create different packaging, but the capability to create a wide variety of shapes in aluminum foil trays helps production be much more efficient. Production efficiency is about doing more for less time, with fewer mistakes and less cost. Modern aluminum foil-making machines have to be quick, precise, and flexible. Here’s how versatile shapes help improve efficiency:

Automation and Advanced Technology

All the machines involved today run the entire production process with the help of automation and advanced technology of CNC systems and servo motors. Using these systems, we can tune settings to make different shapes, which requires no changes in settings. It also ensures that production is faster and error risk is minimized because everything runs on an automatic mode of control.

Optimizing Material Usage

These machines optimize the usage of this material. Manufacturers are able to reduce waste by using the same machine to create differently shaped things. For example, they can alter how big or how small the trays are depending on exactly how much aluminum foil goes about filling a tray. That there will be less leftover material means that the production cost will be reduced, and it will help the environment by decreasing waste.

Reducing the Need for Manual Labor

Manual labor no longer takes center stage, which is when automation comes into play. Previously, these workers would have had to alter molds and machines to change for a different tray-shape; this process took time and more workers. With today’s machines, however, they need fewer people per job. It will reduce labor costs and free up workers to concentrate on other, more important tasks.

Faster Production Cycles

With one machine, we can make different shapes, which speeds up production cycles. Back in the day, factories may have required several machines for various tray shapes. With versatile machines, manufacturers now have the ability to switch between shapes and consequently speed up production times easily. This is extremely crucial when a company has a big order to complete and has to complete it within a short deadline.

What Industries Benefit the Most from Versatile Aluminum Foil Tray Production?

The Versatile aluminum foil-making machines are used by various industries as they provide customized packaging solutions. There are some industries that really benefit from the use of these machines, such as the food packaging, catering, and retail industries. Now, let us see how versatile foil trays are used by each of these industries.

Food Packaging Industry

The food packaging industry is only able to do with aluminum foil trays, which help keep the food fresh and harmless. Because aluminum improves heat retention and helps prevent contamination, these trays are ideal for storing and cooking food.

Companies are able to package all kinds of food, from meals to baked goods to snacks, because they can make trays in different shapes and sizes. For example, circular trays are great for pizza, and rectangular trays are great for lasagna or other prepared meals.

Catering and Meal Delivery Services

Aluminum foil trays are used by catering services and meal delivery companies to package food for delivery. These companies need different trays in different shapes based on meal sizes. Take, for example, a catering company that requires bigger trays for holding a number of foods for parties or delivery service using smaller trays designed for holding individual meals. They produce the right shape for each need, using versatile machines.

Retail and Supermarkets

Versatile aluminum foil trays are also ideal for retailers, supermarkets, and supermarkets in pre-packaged ready-to-eat meals. The trays are stackable and designed to be compatible with store displays. Custom shapes also enable products to stand out on the shelf, thereby causing more customers to buy them. Businesses can quickly turn around trays as if they have versatile machines to satisfy the evolving requirements in the retail market.

How Does the Design of Aluminum Foil-Making Machines Impact Product Quality and Consistency?

Aluminum foil-making machines are designed in such a way that ensures every tray produced is of high quality and consistency. Packaging has to be designed with quality and consistency because both of these attributes are critical to meeting food safety standards and delivery of consistent product delivery every time. Here’s how the design of these machines affects the final product:

Precision Engineering for High-Quality Trays

Advanced aluminum foil-making machines are specially designed with precision engineering to produce every tray exactly as per the shape and size requirement. Advanced sensors, automated systems, and high-tech cameras enable machines to watch the production process.

The business benefits from this because trays are manufactured with the correct thickness, smooth edges, and the correct dimensions so that each tray meets the standards.

Maintaining Uniformity Across Different Shapes

So when you make different design trays, as a user, you want to maintain (almost) the same quality in trays regardless of the difference. The design machines that make these versatile shapes are designed to be consistent.

This ensures that whether that tray is round, square, or rectangular, the quality is the same. Businesses are able to deliver a reliable product every time by keeping the trays consistent in thickness, quality of the aluminum, and strength.

Ensuring Food Safety

Packaging is all about taking care of food safety. Any defect in aluminum foil trays with food therein would compromise the safety of the food, and therefore, the containers must be defect-free.

Modern machines are purposely designed for these machines to meet strict hygiene standards so that machines cannot become contaminated in the manufacturing process. To ensure that the trays are safely cleaned and ready for use in food storage and transportation, manufacturers have installed high-tech systems.

Finally, with an aluminum foil tray-making machine design, you can be assured that the trays are made to exact precision, consistency, and quality. It assists businesses in attaining high food safety standards and offers them dependable packaging.

What Are the Cost Savings Associated with Using a Machine That Creates Versatile Shapes?

If businesses adopt a machine that can produce forms in aluminum foil trays productively, they will save a lot in cost. These machines help manufacturers cut production expenses by increasing efficiency and decreasing waste. Now, let’s see how these machines help save money.

Reduced Labor Costs

Reducing the need for labor is one of the biggest cost savings. On traditional tray-making machines, however, it is often necessary that workers adjust settings or change molds when it is necessary to change between different shapes. However, this is primarily done automatically with versatile machines. That means businesses only need a few workers to run the machines, which saves companies on wages and training costs.

Less Material Waste

Versatile machines also help optimize material usage. Oftentimes, when you are making trays, there is always leftover aluminum foil that needs to be used. Manufacturers can adjust each tray’s size and shape with versatile machines, so they use just the right amount of foil. They provide a way to reduce waste and lower material costs, which can add up over time.

Higher Production Capacity

By using machines to make multiple shapes using one machine, businesses can produce the trays quickly and efficiently. Large orders can now be met in less time because of faster and faster production cycles. Now, businesses can produce more, fulfill more orders, and do all this without the need for more equipment and workers.

Long-Term Savings

This machine is undoubtedly a smart long-term investment. Businesses no longer need to buy different machines to make different shapes; they can use one machine for a host of tray types. It also saves on equipment, maintenance, and storage space costs.

To conclude, companies can minimize labor expenses, reduce material squandering, and streamline generation speed when aluminum foil tray makers are flexible.

Conclusion

Moreover, aluminum foil-making machines, which make various shapes of versatile products, are transforming the manner in which businesses approach packaging. These machines, which are capable of producing various tray shapes quickly and as required, not only help companies save money and curtail waste but also help companies meet the growing demand for customized packaging.

In food packaging, catering, and retail industries, they are critically important for supplying excellent, safe, and attractive trays.

However, as technology advances, we can only expect better precision, faster production, and more eco-friendly options from these machines. From increasing production efficiency to reducing costs to meeting customer needs, functional aluminum foil-making machines are obviously an important investment for businesses that want to stave off competition.

Call to Action

Ready to take your packaging to the next level? Invest in our high-quality aluminum foil-making machine today and experience unmatched efficiency and versatility. Visit FoilOnline to learn more and get started. Don’t wait—contact us now for a free consultation! Get in touch today!