Revolutionizing Packaging: Applications and Benefits of Aluminum Foil Lid-Making Machines

Have you ever paused to think about the aluminum foil lids on your favorite yogurt container or takeaway meal? Those shiny, perfectly cut covers are more than just a convenience; they’re essential for keeping food fresh, safe, and ready to enjoy. Behind every one of these lids is a powerful tool known as the aluminum foil lid-making machine. These machines are transforming how industries package their products, making it faster, cleaner, and more reliable.

From food packaging to cosmetics and medicine, aluminum foil lids have become a part of our daily lives. But how are they made, and why are they so important? Let’s explore the fascinating role of aluminum foil lid-making machines and the many ways they contribute to the modern packaging industry.

What Is an Aluminum Foil Lid-Making Machine?

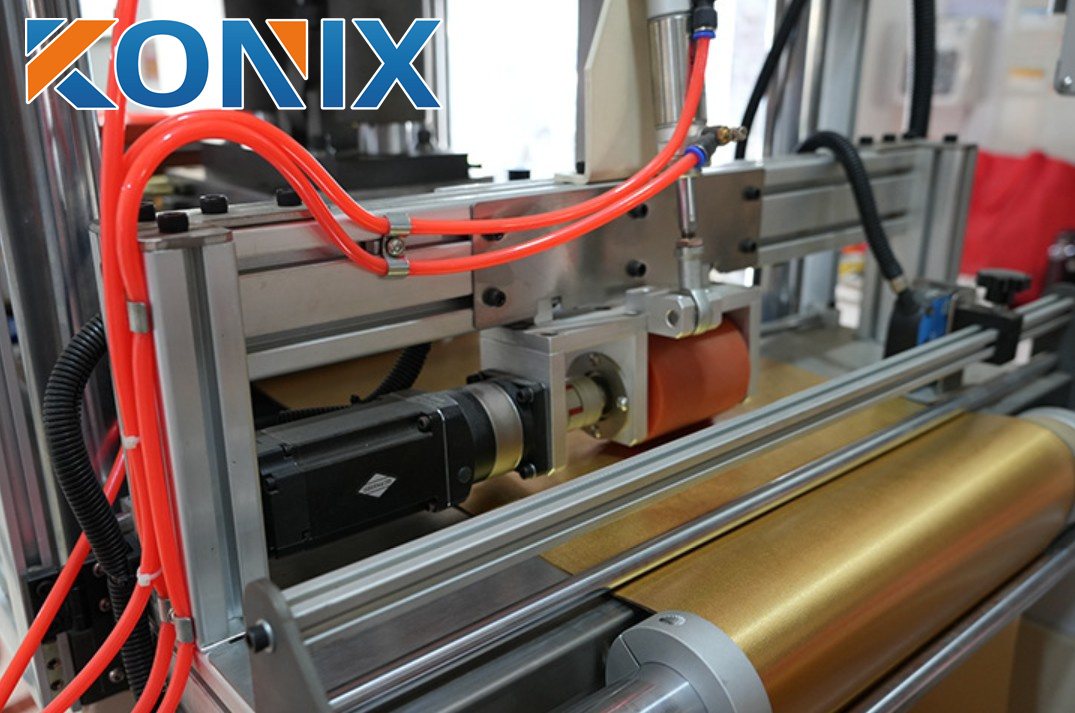

At first glance, an aluminum foil lid-making machine might look like just another piece of factory equipment, but it’s far more sophisticated than that. It takes large rolls of aluminum foil and transforms them into lids with precise shapes and sizes. These lids are then used to seal containers in various industries.

The process involves several steps. First, the foil is fed into the machine, where it’s stamped, cut, and formed to the exact specifications required. The machine’s cutting tools ensure the lids are smooth and uniform, while forming technology creates the perfect fit for different types of containers.

Modern machines often include advanced features like automation. Automated machines can operate with minimal human involvement, increasing productivity and reducing errors. They are also capable of customization, allowing businesses to design unique lids with branding elements such as logos, patterns, or text. This capability helps companies stand out in competitive markets.

In short, these machines are a blend of precision engineering and high-tech automation, ensuring that every lid is crafted to perfection.

Industries That Depend on These Machines

Aluminum foil lids are so versatile that they are used across a variety of industries. Some of the most prominent sectors that rely on these machines include:

- Food Packaging

The food industry is one of the largest users of aluminum foil lids. From yogurt containers to takeaway trays, these lids ensure freshness and hygiene while providing a leak-proof seal. They also make containers stackable and easy to transport, which is crucial for large-scale food production and delivery. - Pharmaceuticals

In the pharmaceutical industry, safety and hygiene are paramount. Aluminum foil lids play a critical role in protecting medicines from contamination. Whether it’s a blister pack for pills or a seal for a liquid medicine bottle, these lids create a barrier against moisture, air, and bacteria, ensuring the product remains effective and safe to use. - Cosmetics

For beauty and skincare products, aluminum foil lids offer both protection and aesthetics. They keep products like creams and serums fresh while also providing a sleek, professional appearance. Many brands use customized lids to add a touch of elegance to their packaging, enhancing their appeal to consumers.

By meeting the needs of such diverse industries, advanced aluminum foil lid-making machines prove their value as a versatile and essential tool in manufacturing.

Applications of Aluminum foil lid-making machines That Make a Difference

Aluminum foil lid-making machines are incredibly versatile. Their applications extend far beyond simply covering containers. Let’s take a closer look at some of their key uses:

Food and Beverage Packaging

- Sealed Food Trays: Machines produce lids that fit perfectly onto aluminum food trays, making them ideal for frozen meals, baked goods, and ready-to-eat snacks. These lids provide an airtight seal, preserving the food’s freshness and flavor.

- Beverage Cups: Hot drinks like coffee or tea are often served in cups sealed with foil lids. These lids prevent spills and maintain the beverage’s temperature for longer periods.

- Flexible Pouches: Some machines also create foil seals for flexible pouches, commonly used for sauces, soups, and other liquid products.

Pharmaceutical Packaging

- Blister Packs: One of the most common applications in this industry is the production of blister packs. These lids seal individual doses of medicine, keeping them safe from contamination and ensuring precise dispensing.

- Heat-Sealed Bottles: Aluminum foil seals are also used for medicine bottles, providing a tamper-evident layer that guarantees product integrity.

Cosmetic Packaging

- Jar Lids: Skincare products like moisturizers and scrubs often come in jars sealed with foil lids. These lids not only protect the product but also offer a luxurious feel.

- Custom Shapes: High-performance aluminum foil lid-making machines can create decorative lids with intricate patterns, adding to the product’s aesthetic appeal.

Industrial Applications

While food, pharmaceuticals, and cosmetics are the primary industries, these machines also serve industrial purposes. For instance, they can create lids for chemical containers or specialty products requiring secure, durable seals.

These varied applications demonstrate the machine’s ability to adapt to different industries and meet specific packaging needs.

Benefits for Businesses and Consumers

Aluminum foil lid-making machines are a win-win for both businesses and consumers. Let’s break down the benefits:

For Businesses

- Efficiency: Automation allows companies to produce large volumes of lids quickly and with consistent quality. This reduces production costs and ensures timely delivery.

- Branding Opportunities: With customization features, businesses can design unique lids that showcase their brand, enhancing customer recognition.

- Eco-Friendly Packaging: Aluminum’s recyclability aligns with global sustainability trends, helping businesses meet consumer demands for greener packaging options.

For Consumers

- Convenience: Sealed lids make it easier for consumers to handle, store, and transport packaged goods. They also ensure that products remain fresh until they are opened.

- Safety: Whether it’s a tamper-proof seal on a medicine bottle or a hygienic cover on food, aluminum foil lids provide peace of mind by ensuring the product’s integrity.

- Quality Assurance: Lids made with these machines are durable and reliable, giving consumers confidence in the product’s quality.

Advancements in Aluminum Foil Lid-Making Machines

The evolution of aluminum foil lid-making machines has revolutionized packaging across industries. Modern machines are designed with cutting-edge technology to improve efficiency, precision, and adaptability, meeting the diverse needs of businesses.

Automation is one of the most significant advancements in these machines. Fully automatic models streamline the production process, reducing the need for manual labor while increasing output. These machines can operate continuously, producing thousands of lids per day with consistent quality. This not only saves time but also ensures that every lid meets the exact specifications required for its application.

Another key feature is customization. Today’s machines can create lids in a variety of shapes, sizes, and designs, accommodating the unique packaging requirements of food, pharmaceuticals, and cosmetics industries. Many models also integrate eco-friendly technologies, optimizing material usage and minimizing waste.

With these advancements, aluminum foil lid-making machines continue to set new standards for packaging innovation.

Choosing the Right Machine

Investing in a premium aluminum foil lid-making machine is a significant step for any business, so it’s important to choose one that meets your specific needs. Here are the key factors to consider:

Production Needs

Start by assessing your daily production requirements. If your business operates at a large scale, you’ll need a high-capacity machine capable of producing thousands of lids efficiently. Smaller businesses or niche markets might find compact machines more suitable for their output levels.

Automation Level

Automation can make a big difference in productivity. Fully automatic machines handle most of the work on their own, reducing the need for manual labor and minimizing human error. Although these models often require a higher initial investment, they can save money over time. On the other hand, semi-automatic machines might be a better fit for businesses with smaller budgets or less need for high-speed production.

Customization Options

Flexibility is key if you serve multiple industries or offer a range of products. Choose a machine that allows you to create lids in different shapes, sizes, and designs. This ability to customize helps your business meet specific client demands and stand out in competitive markets.

Maintenance and Support

A reliable lid-making machines machine requires consistent upkeep, so prioritize options with strong after-sales service. Quick access to replacement parts and technical support will minimize downtime and keep your production line running smoothly.

With careful consideration of these factors, you’ll find a machine that boosts your efficiency, reduces costs, and supports your business growth.

Conclusion

Aluminum foil lid-making machines are an unsung hero in modern manufacturing. They’re the reason your food stays fresh, your medicine remains safe, and your skincare products look as good as they feel. These machines are versatile, efficient, and essential for industries that prioritize quality and reliability.

For businesses, they offer a chance to improve operations, reduce costs, and meet customer expectations. For consumers, they provide convenience, safety, and peace of mind.

If your business is ready to embrace the future of packaging, there’s no better time to invest in one of these incredible machines. With the right equipment, you can take your packaging process to the next level and make a lasting impression on your customers.

The journey to better packaging starts here—are you ready to lead the way? Contact us today!