Production costs of manufacturing empty aluminum Nespresso capsules

The production costs associated with manufacturing empty aluminum Nespresso capsules can include the following:

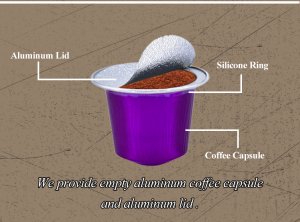

- Raw Materials: The primary cost is the aluminum material used to manufacture the capsules. The cost of aluminum can vary depending on factors such as market prices, quantity purchased, and quality requirements. Other materials, such as adhesive liners or coatings for the capsules, may also contribute to the raw material costs.

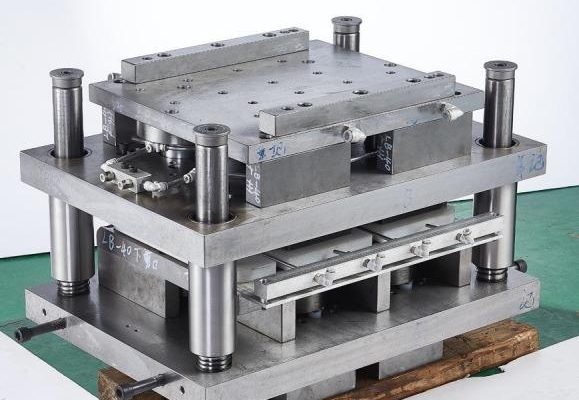

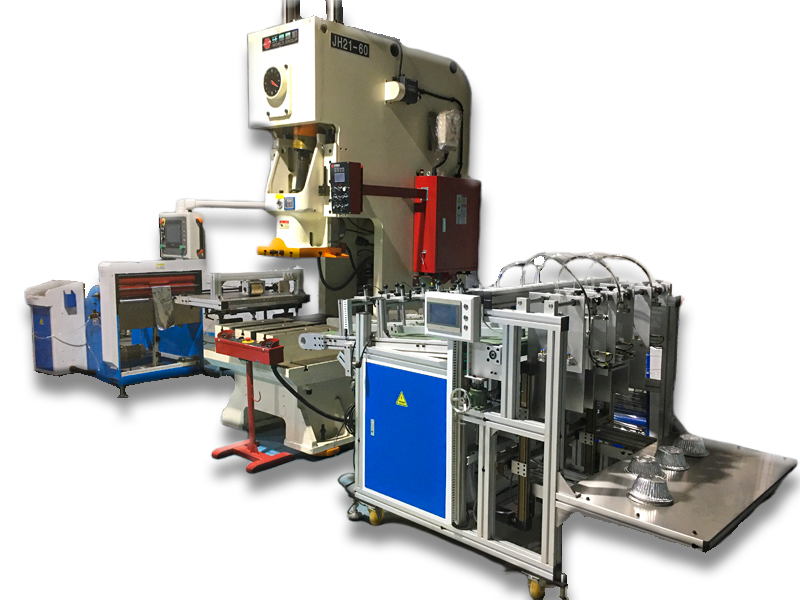

- Manufacturing Equipment: Specialized equipment is required for capsule production, including machinery for capsule forming, cutting, and shaping, as well as any additional equipment for processes like sealing or printing. The cost of the equipment will depend on its complexity, capacity, and automation level.

- Labor: Labor costs involve the wages and benefits of the production personnel involved in the manufacturing empty aluminum Nespresso capsules process. This includes operators, technicians, quality control personnel, and other staff members required for production and supervision. The number of employees needed will depend on the scale of production and the level of automation.

- Energy and Utilities: Manufacturing empty aluminum Nespresso capsules processes require energy for heating, cooling, and operating machinery. The cost of electricity, water, gas, or other utilities used in the production facility contributes to the overall production costs.

- Packaging Materials: Packaging materials, such as boxes or trays, are required to package and transport the empty capsules. The cost of these materials, including any branding or labeling components, should be considered.

- Quality Control: Ensuring the quality of the capsules and meeting industry standards requires quality control measures. This includes equipment for testing and inspection, as well as trained personnel to perform quality checks. The cost of quality control activities and any necessary equipment should be accounted for.

- Regulatory Compliance: Compliance with relevant regulations and certifications may involve costs such as obtaining necessary certifications, conducting audits, and implementing quality management systems. These costs ensure that the production process meets the required standards and regulations.

- Overhead Expenses: Overhead expenses include various indirect costs such as facility rent, maintenance, insurance, administrative expenses, and marketing expenses. These costs are necessary for the overall operation of the manufacturing facility and should be factored into the production costs.

It’s important to note that the specific costs can vary based on factors such as location, production volume, equipment efficiency, labor rates, and other operational considerations. Overall and according to calculation, manufacturing empty aluminum Nespresso capsules is a good way to invest and you will earn higher profits compared to that of aluminum foil food containers