Wrinkle-free Aluminum Foil Container Mould

حجم الحاويات: على الشرط

ماركة: كونيكس

مكان المنشأ: قوانغتشو, الصين

نوع مدفوعة: هوائي

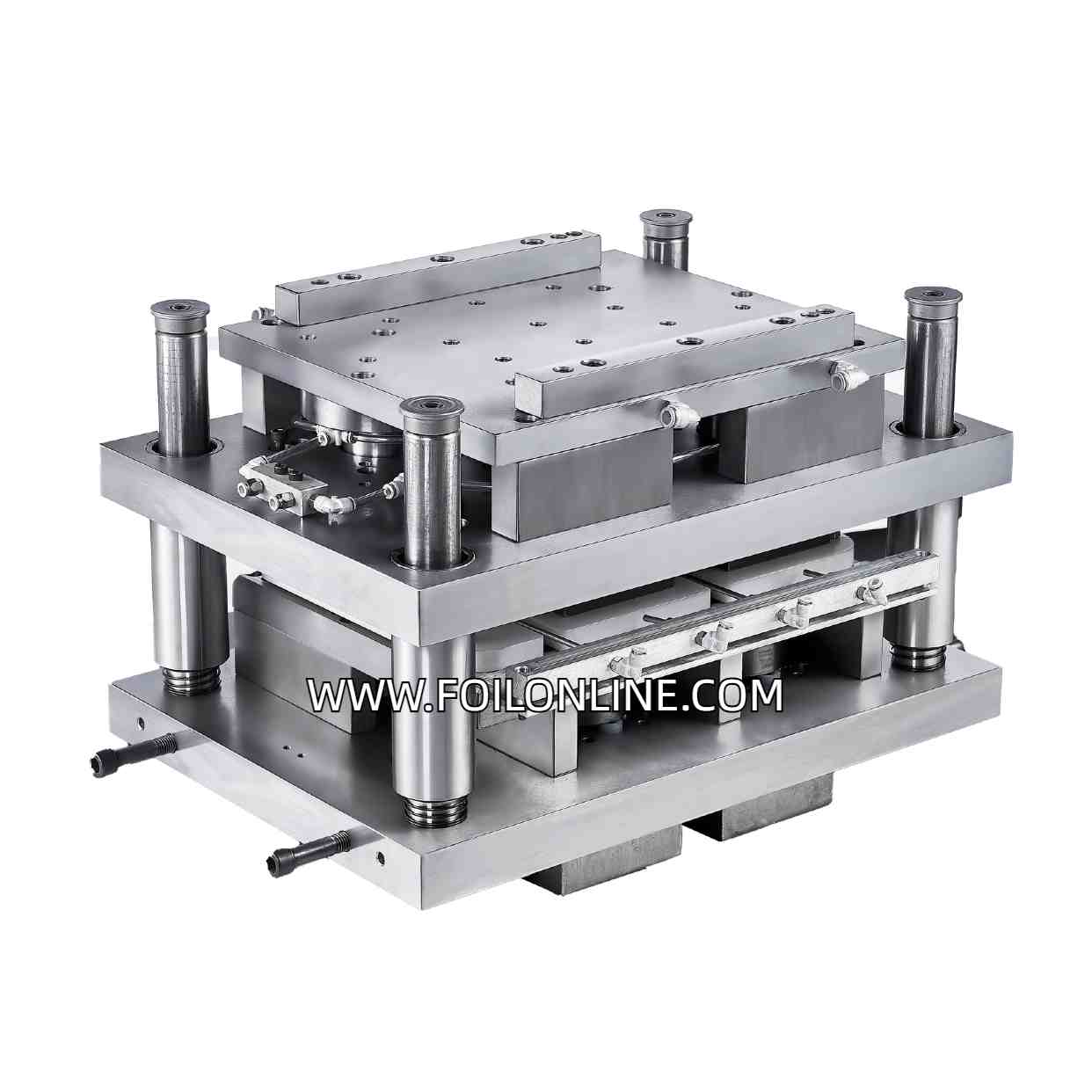

Wrinkle-free Aluminum Foil Container Mould

Wrinkle-free Aluminum Foil Container Mould is specially designed moulds used in the production of smooth wall aluminum foil containers. These moulds are used in the manufacturing process to shape and form the aluminum foil into the desired container shape.

The Wrinkle-free Aluminum Foil Container Mould is typically made from high-quality materials DC53 or D2. They are precision-engineered to ensure accurate and consistent shaping of the aluminum foil.

PRODUCT INTRODUCTION

- Flexibility in aluminum foil container options: We offer lacquered or unlacquered containers with the choice of plain or colorful finishes.

- High-quality steel molds: Our molds are constructed using imported high-quality steel. The critical areas of the molds undergo high-temperature heat treatment to achieve the desired hardness, ensuring excellent quality and long lifespan.

- Multi-cavity mold design and production: We have the capability to design and manufacture molds with multiple cavities, whether it’s for normal airline containers or special deep smooth-wall containers.

- Versatile compartment options: Our mold design and production extend to both single compartment and multi-compartment containers, providing flexibility to meet diverse customer needs.

خدمة المبيعات

- خدمة الآلات في الخارج: لدينا فريق من المهندسين متاح لتقديم الخدمة والدعم للآلات في الخارج, ضمان المساعدة والصيانة في الوقت المناسب.

- التدريب وتدريب العمال: نحن نقدم خدمات التدريب ويمكننا المساعدة في تدريب العاملين لديك على تشغيل القوالب والآلات بفعالية, تعزيز مهاراتهم.

- المساعدة التقنية: نحن نقدم المساعدة الفنية المستمرة لدعم المستخدمين طوال مراحل التثبيت, عمليات الاختبار, والصيانة المستمرة للآلات.

WHY CHOOSE OUR Wrinkle-free Aluminum Foil Container Mould

- Extensive experience in aluminum container mold production and customization

- High-tech molds that are easy to operate and maintain

- Ability to build molds based on customer requests, including different rim configurations (Full Curl, Hemmed Vertical Edge, Interrupted Vertical Curl)

- Production of molds according to customer specifications, including various shapes, الأحجام, and cavity numbers

- Use of high-quality steel for all tools

- Heat-treated flow areas for proper hardness

- Reliable and long-lasting molds

- Focus on establishing long-term customer relationships

- Timely delivery of spare part replacements within two weeks.

""

1