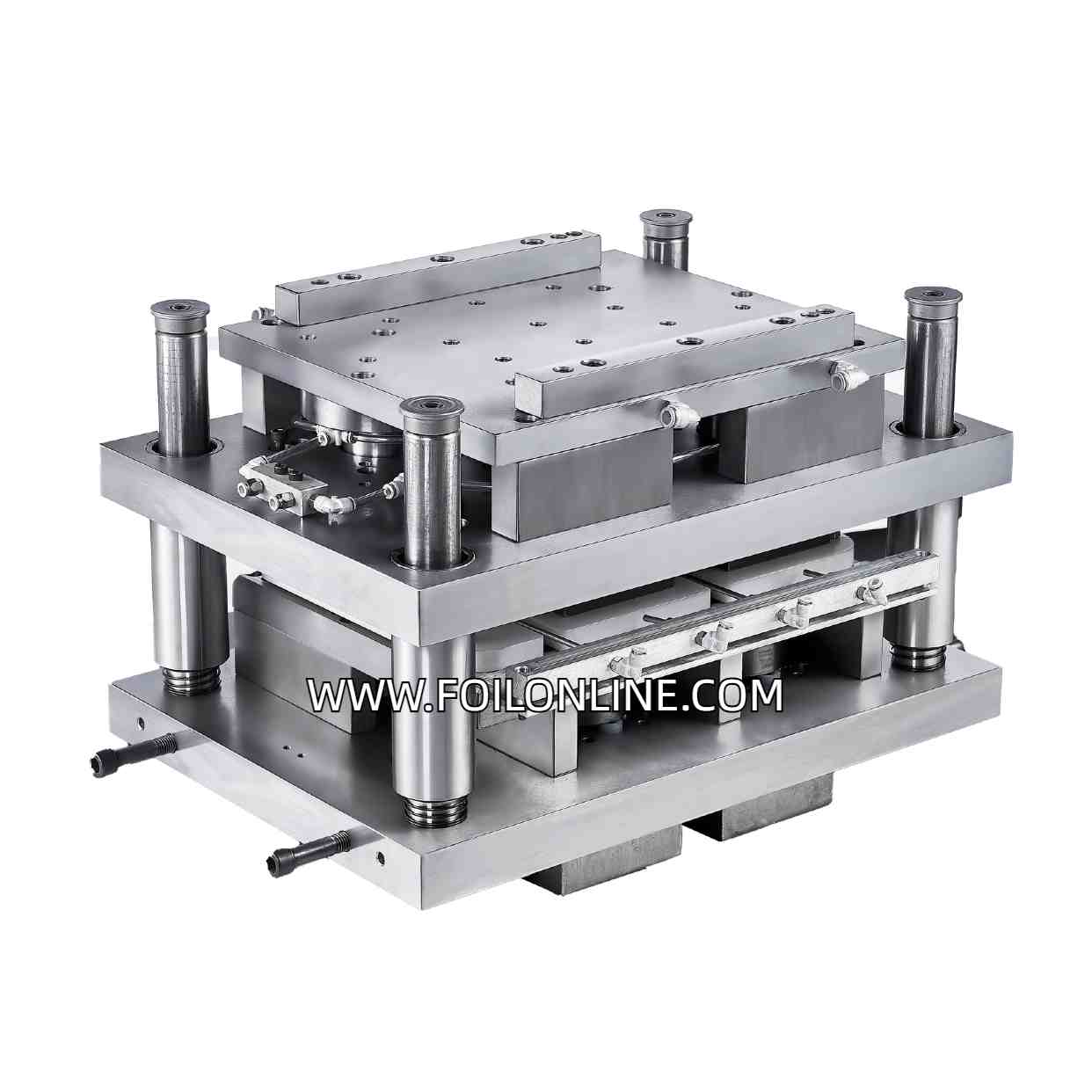

Empty Aluminum Coffee Capsule Mould

Specification: One cavity, two cavity, muti cavity, etc.

Container size: On requirement

Brand: KONIX

Place of Origin: Guangzhou, China

Driven Type: Pneumatic

Empty Aluminum Coffee Capsule Mould

INTRODUCTION

An empty aluminum coffee capsule mould is a tool used in the production of coffee capsules. It is typically made of highest quality mould steel to ensure proper heat distribution and durability. The mould is designed to shape and form the coffee capsules, providing a consistent size and shape for the final product.

FEATURE

- The technology is unique and exclusive in China, with the capacity of production of machinery could vary from 6000 pcs/hour.

- The flange tooth technique which is done once by punch is supported, so as to be used without any ring attached.

- Capsule appearance and technique can be customized on customer request.

- The mould is is made of imported high-quality mold steel DC53 or D2 etc.

- After quenching and tempering, vacuum heat treatment and deep cooling treatment, the mold is equipped with precision guide posts and bushings, slow wire cutting and precision surface grinding, and all accessories are made with precision.

- Konix provides one stop service to manufacture empty coffee capsules including making machine, various accessories and coffee capsule glue dispensing machine.

Production Capacity

The capacity of production of konix capsule machinery could be up to 6,000 pcs/hour

SALES SERVICE

- Overseas machinery service: Our team of engineers is available to provide service and support for machinery overseas, ensuring timely assistance and maintenance.

- Internship and worker training: We offer internship services and can assist in training your workers to operate molds and machines effectively, enhancing their skills.

- Technical assistance: We provide constant technical assistance to support users throughout the installation phases, testing processes, and continuous maintenance of the machines.

Production Flow of making capsules by Empty aluminum coffee capsule mould

- The feeder feeds the material into the pneumatic press.

- The material goes into the mold and is pressed into shape.

- Products are made and blown out

- Products are transferred by conveyer belt or stacker

Whether you require modifications to size, capacity, functionality, or automation features of empty aluminum coffee capsule mould, our team of experts works closely with you to design and manufacture a machine that precisely fits your production goals.

Our production line enhance productivity and streamline operations, but it also offers reliability. Built to last, our machines are durable and designed for continuous performance, minimizing downtime, and allowing you to meet your production targets consistently. Our molds use mold steel imported from Japan to ensure stable use for up to ten years