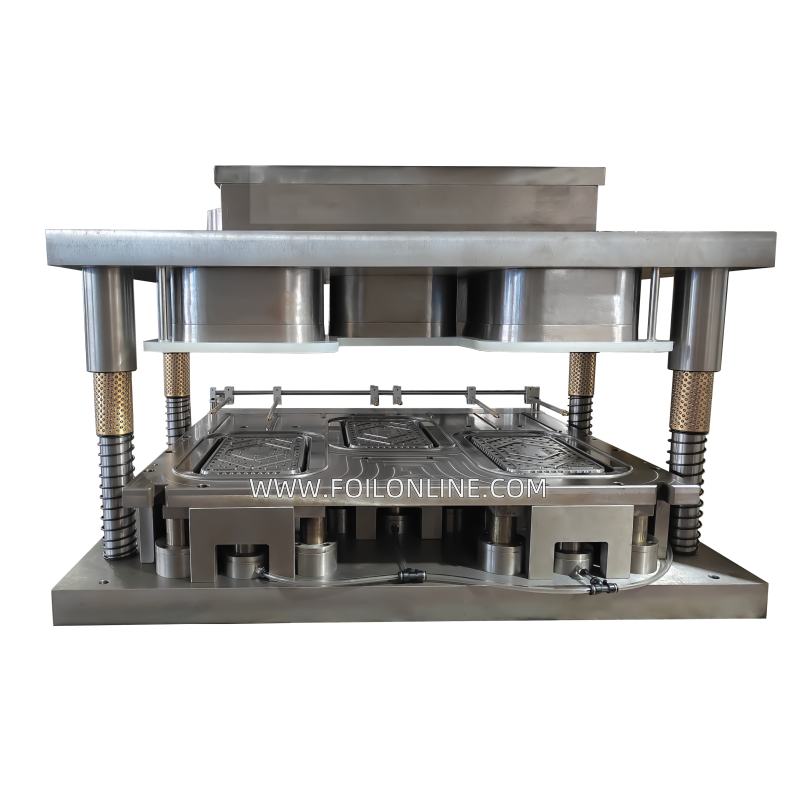

Double Cavity Aluminium Foil Container Mould

Specification: One cavity, two cavity, etc.

Container size: On requirement

Brand: KONIX

Place of Origin: Guangzhou, China

Driven Type: Pneumatic

Double Cavity Aluminium Foil Container Mould

INTRODUCTION

- High-quality steel construction: KONIX Double Cavity Aluminium Foil Container Mould is built with high-quality steel, and the flow area undergoes heat treatment to ensure excellent hardness and long operating life.

- Pneumatic rebound device: The molds incorporate a pneumatic rebound device, enhancing flexibility and performance.

- Efficient one-step process: Our advanced processing techniques enable the molds to efficiently complete cutting, shaping, blanking, and curing in a single step.

- Versatile mold options: We offer both single-cavity and multi-cavity molds, catering to various container types with different rim styles (G style, L style, IVC, Folded style).

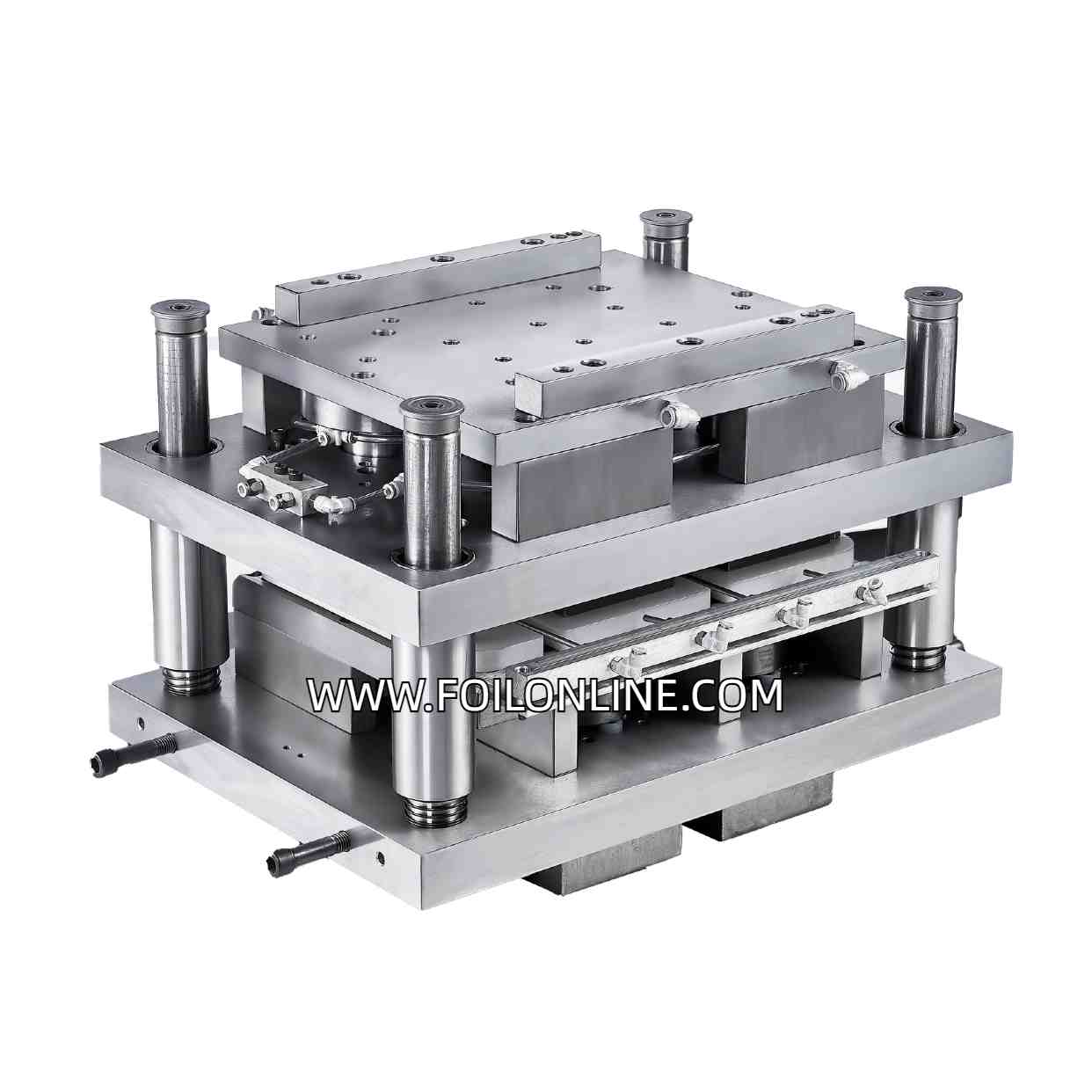

- Integrated design and manufacturing: Our fully integrated 3D CAD/CAM package allows for seamless transition from design to machining. This results in precision tools produced in a timely manner.

- Compatible with different presses: Our tools can be configured to function with almost any type of press, ensuring compatibility with a wide range of machinery.

- Simple and robust design: Our tool design is simple and robust, facilitating easy setup and operation with minimal downtime and maintenance costs.

- Advanced technology: We incorporate only advanced and tested technology into the tool build, ensuring optimal performance and reliability.

FEATURE

- Made of imported high-quality mould steel. Mold Core is made of DC-53, SKD11 mould steel from Japan.

- With the flexibility of gas, it adopts the principle of gas compression and rebound, high precision, more stable.

- Manufactured with best heat treatment and WEDM-LS process, with high processing accuracy within 0.005mm.

- Multi-cavity mold capability: We can produce molds with multiple cavities, accommodating both single compartment and multi-compartment containers.

- Versatile compatibility: Our molds are suitable for use with various machines or presses.

- The processing of aluminum foil containers is completed from cutting, stretching, forming, curling, and finished products at one time, including various sides (G side, L side or IVC, folding side, etc.).

SALES SERVICE

- Overseas machinery service: Our team of engineers is available to provide service and support for machinery overseas, ensuring timely assistance and maintenance.

- Internship and worker training: We offer internship services and can assist in training your workers to operate molds and machines effectively, enhancing their skills.

- Technical assistance: We provide constant technical assistance to support users throughout the installation phases, testing processes, and continuous maintenance of the machines.

Whether you require modifications to size, capacity, functionality, or automation features of Double Cavity Aluminium Foil Container Mould, our team of experts works closely with you to design and manufacture a machine that precisely fits your production goals.

Our production line and aluminum foil container mould 2 Cavity enhance productivity and streamline operations, but it also offers reliability. Built to last, our machines are durable and designed for continuous performance, minimizing downtime, and allowing you to meet your production targets consistently. Our molds use mold steel imported from Japan to ensure stable use for up to ten years