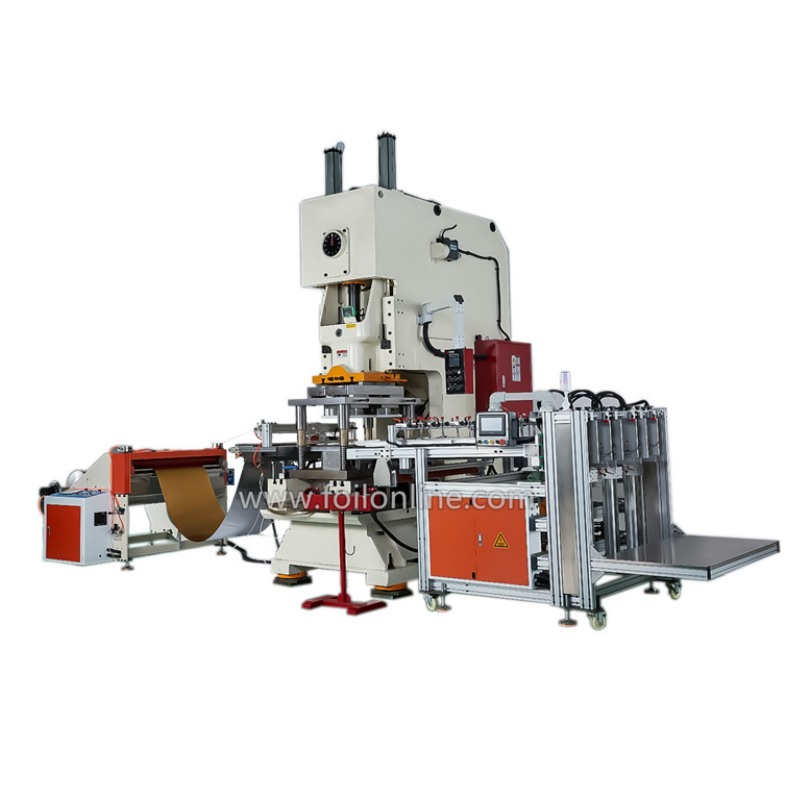

New Series Aluminum Foil Tray Making Machine

New Series Aluminum Foil Tray Making Machine

I. BRIEF INTRODUCTION

The KONIX New Series Aluminum Foil Tray Making Machine is a cutting-edge solution for aluminum foil container manufacturing:

- It boasts automatic foil feeding, auto lubrication, mold forming, and automatic collection, optimizing precision, speed, and operational efficiency while reducing labor requirements.

- The inclusion of a precise stepper motor enables fine-tuning of the aluminum foil entry speed, coupled with a high-speed vertical pneumatic press and high-precision self-developed mold for swift production.

- Noteworthy components include PLC and converter systems sourced from prestigious brands like Mitsubishi Japan or Chinese Inovance, along with electrical parts from Schneider or other reputable suppliers. This selection guarantees meticulous machine control and feeding accuracy, with an impressive tolerance of ±0.03mm.

- The aluminum foil container mold creation involves a blend of low-speed wire cutting and high-precision CNC processing techniques to ensure product accuracy and expedite production.

- KONIX provides the option for customized mold designs to align with specific requirements, drawing on their extensive mold expertise to enhance the aesthetics and functionality of foil containers.

The KONIX New Series Aluminum Foil Tray Making Machine serves as a reliable tool to help achieve your business objectives and excel in the competitive market landscape.

Ⅱ. PRODUCTION LINE CONFIGRATION

- Automatic Foil Feeder

The automatic foil feeder consists of essential features:

Precise Stepper Motor: Controls the speed of aluminum foil entering the press with accuracy.

Height Adjustment: Allows operators to adjust the entrance height of the foil for proper alignment with the press tool.

Reel Shaft System: Facilitates quick and easy roll exchange while maintaining optimal axial alignment.

Lubrication System: Provides lubrication to the foil strip, eliminating the need for pre-lubricated raw material and offering flexibility for specific lubricant requirements.

Technical data:

- Model: 800

- Material width: ≤800mm

- Feeding accuracy: ±0.03mm

- Shaft Diameter: ø 76mm

- Work Power: 1.5kw

- Loading weight: 2000kg

- Number of rollers: 3 sets

- Overall weight: 600kg

- Decoiler dimensions: 1420mm*1460mm*1180mm

- Precise Length controller: 600mm*1010mm*900mm

- Lubricant refill way: Auto filtrate

- Lubricant coating consumption: 300-600mg/sqm

- Foil lubricant tank material: SUS304

- Length controller structure material: aluminum profile

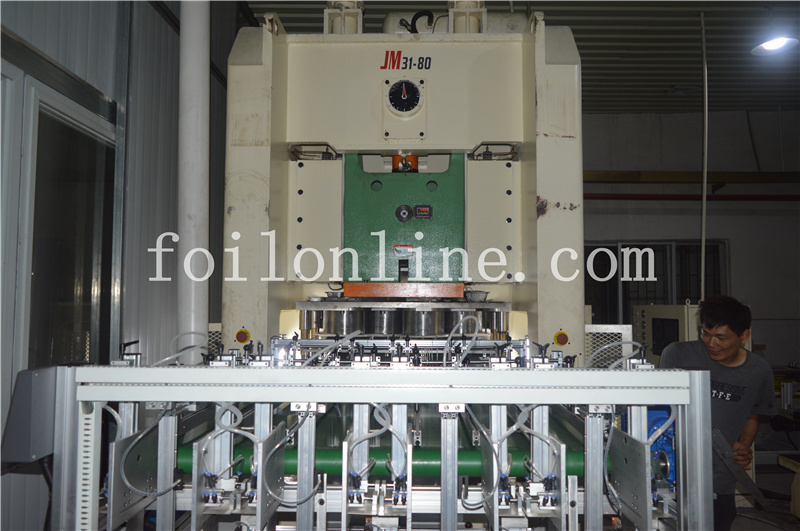

2. Precision Pneumatic Press

The precision pneumatic press is special designed and customized press for the New Series Aluminum Foil Tray Making Machine. The nominal capacity is 600KN. And its max die set height, slide stroke and bolster are all customized only for KONIX self-developed mould. The press main motor adopts German Siemens brand, and Schneider and Omron for other main electrical parts.

- Nominal capacity: 600KN

- Press type: Pneumatic

- Slide of stroke: 220mm

- Max die set height: 450mm

- Motor Power: Siemens 5.5kw

- Overall weight: about 5000kg

- Work table design: left and right separated

- Working speed: 30-80circles/min

- Hydraulic overload protection: Yes.

- Mould set height display method: Digital.

- Variable frequency speed adjustment: Yes

- High Precision Mould

The Aluminum Foil Container Mould is a critical tool essential for producing aluminum foil containers efficiently. Here are key points about its features and manufacturing:

- Utilizes gas compression and rebound principles for flexibility, high precision, and stability.

- Manufactured using top heat treatment and WEDM-LS process to ensure high processing accuracy within 0.005mm.

- Enables streamlined processing of aluminum foil containers from cutting, stretching, forming, curling, and final product creation in one go, accommodating various container side types.

- Offers a normal service life ranging from 10 million to 100 million cycles (excluding wearing parts), with shears, guide pillars, cylinders, and crimping grooves as common wearing parts.

- Made from materials like 45 carbon steel, DC53, CR12MOV, and undergoes processes like quenching, tempering, vacuum heat treatment, and deep cold treatment for durability. Precision guide posts, guide bushes, slow wire cutting processing, precision surface grinding, and fine workmanship on all accessories ensure quality production.

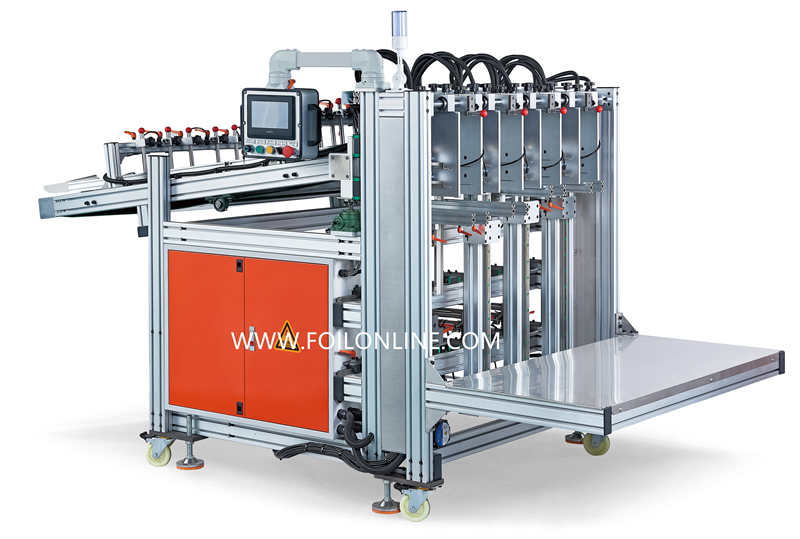

- Automatic Stacker

Structure: The mold features an aluminum profile frame structure, combining aesthetic appeal with robustness, making it suitable for accommodating various types and sizes of aluminum foil containers.

Operation: Users can conveniently manage the collection process through a movable touch system. This system allows for easy configuration of collection quantity, control of conveyor belt speed, adjustment of collection platform height, and counting of collected containers. By utilizing precise tools on the collection machine, users can effortlessly modify the container collection size.

Electrical: In collaboration with INOVANCE, a renowned global industrial automation provider, the mold incorporates a comprehensive control system comprising a display, PLC, inverter, motor, and more. The utilization of this integrated system ensures a stable and smooth operational experience when using the New Series Aluminum Foil Tray Making Machine.

| Model | KN-2 | KN-3 | KN-4 | KN-5 | Customization/Remarks |

| Quantity of Lane | 2 | 3 | 4 | 5 | – |

| Conveyor belt lifting stroke | 200mm | 200mm | 200mm | 200mm | – |

| Container Dimensions (L*W) | 80-260 * 80-380 | 80-240 * 80-380 | 80-210 * 80-380 | 80-200 * 80-380 | Customization |

| Voltage | 220V~415V | 220V~415V | 220V~415V | 220V~415V | Customization- |

| Dimensions (L*W*H) | 2560*1130*1550mm | 2560*1430*1550mm | 2560*1680*1550mm | 2560*1930*1550mm | – |

| Main Function | Products Counting, Stacking Quantity Setting, Height lifting, Blowing Setting, Speed Setting, Rail Setting | – | |||

| Language | English and Chinese | – | |||

| Discharge Detection | Support products discharge detection from the press machine | – | |||

| Lifting System | 2 Units of Linear Guide Cylinders | System automatic control | |||

| Other Support System | Photoelectric and Optical Fiber Sensors | – | |||

| PLC | INOVANCE H3U-3624MT-XA | – | |||

| Touch Screen | INOVANCE IT7070T | Touch Screen Panel movable design | |||

| Frequency Converter | INOVANCE MD200S-1.5B | – | |||

- Electrical Control System

The New Series Aluminum Foil Tray Making Machine is technologically advanced, with a focus on efficient control and automation:

- It is PLC-controlled, allowing users to conveniently set and monitor production speed and quantity from the machine’s interface.

- The control system integrates Chinese Inovance PLC with renowned brands like Schneider and Omron for other components, ensuring reliability and performance.

- The partnership with INOVANCE, a leading global industrial automation provider in China, ensures a comprehensive control system encompassing display, PLC, inverter, motor, and more, resulting in a stable and smooth user experience.

- For custom requirements, the control system can be tailored to include internationally acclaimed brands like Mitsubishi from Japan or Siemens from Germany, offering flexibility and adaptability to suit specific needs.