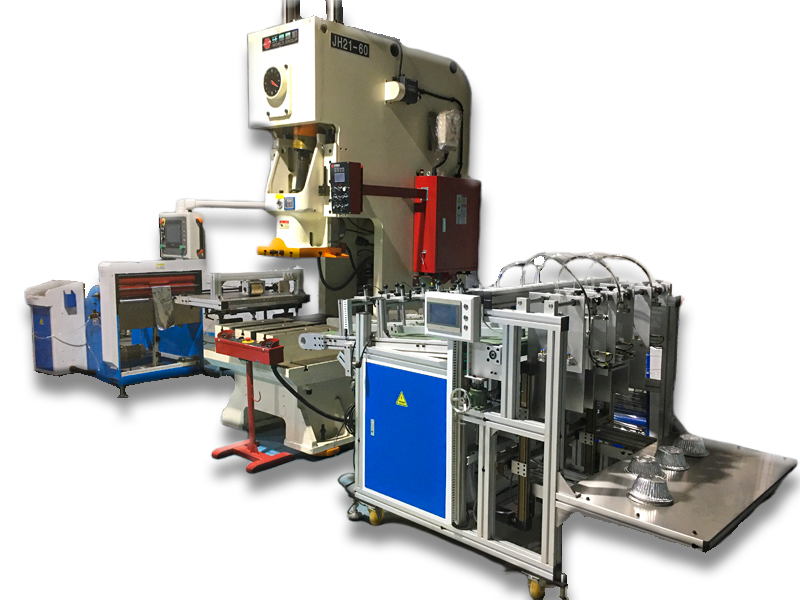

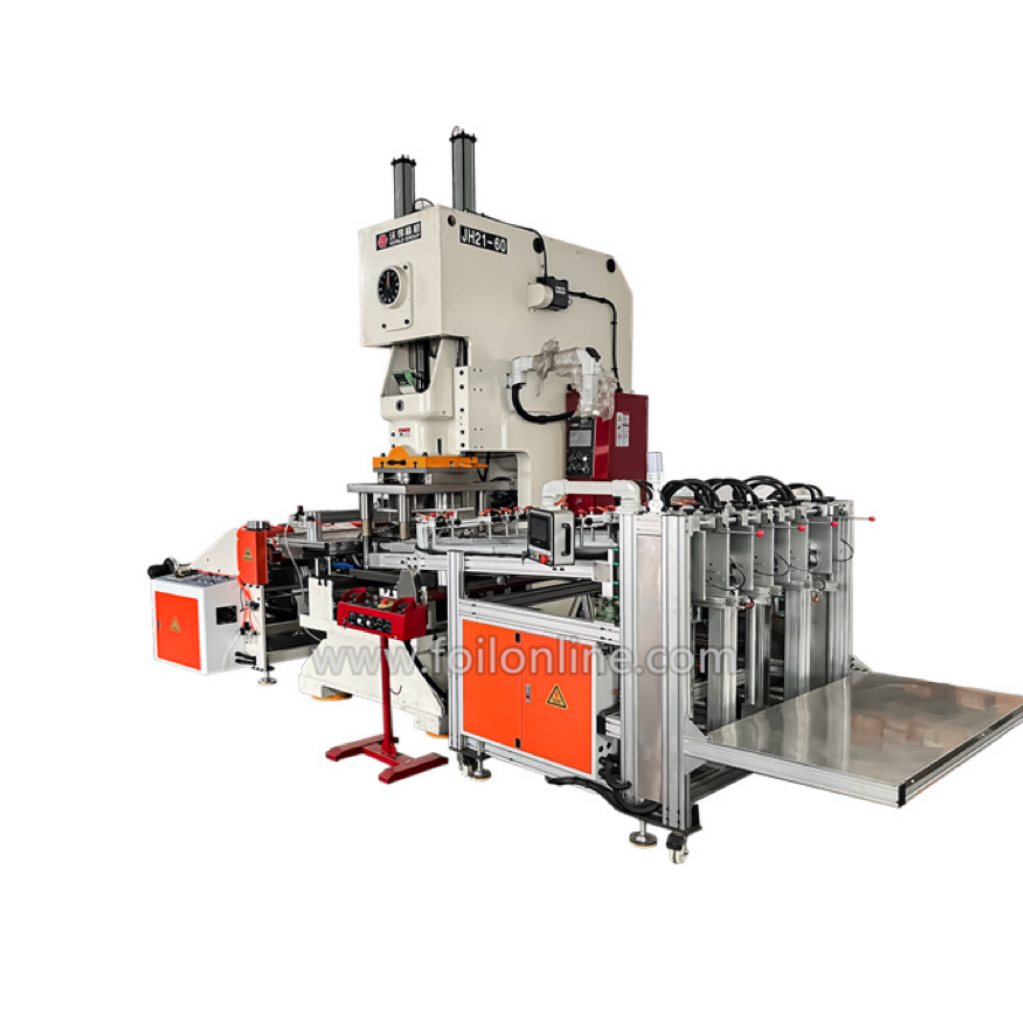

Automatic Aluminium Foil Container Making Machine KN-63T

Leading Manufacturer Of Fully Automatic Aluminium Foil Container Making Machine, which is High Speed Professional Production Line.

Automatic Aluminium Foil Container Making Machine KN-63T

INTRODUCTION

The entire Automatic Aluminium Foil Container Making Machine KN-63T adopts mechatronics design and the integrated electrical control for feeding and press adopts independent system design, which is safe and anti-interference. The touch screen is hung on the left side of the press, which is easy to operate. The stacker is installed on one side and work independently . The PLC program logic of the entire production line is perfectly matched, which greatly improves the production efficiency of the entire machine, making it more intelligent and humane.

FEATURE

- This production line can work automatically. Worker operates the machine through electric control system and collect the stacked products conveniently.

- Machine can be designed and manufactured according to customer’s requirment and customer’s target price.

- Top Safety and long lifetime,high precision control of feeding step and speed.

- Wet clutch pneumatic punch, long service life, low noise

- The replacement of the mold is convenient and easy to change.

CONFIGURATION

- Auto-lubricated Foil Feeder

- Pneumatic Press for coffee capsule

- Foil container mould

- Capsules Stacker

- System control touch screen

- Foil Scrap System

- Electric cabinet

Production Capacity

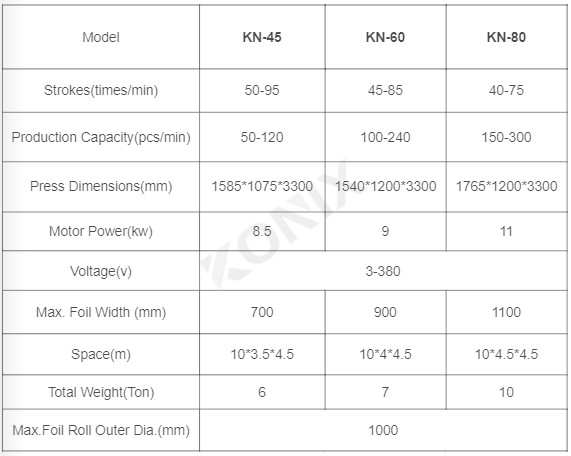

The capacity of production of konix aluminum foil container could vary from 50 – 300 pcs/min

Production Flow of Automatic Aluminium Foil Container Making Machine KN-63T

- The feeder feeds the material into the pneumatic press.

- The material goes into the mold and is pressed into shape.

- Products are made and blown out

- Products are collected by stacker

TECHNICAL DATA

KONIX provides one-stop solution for aluminum foil container production line including aluminum foil container mould.