Aluminium Foil Container Stacking Machine with Counting

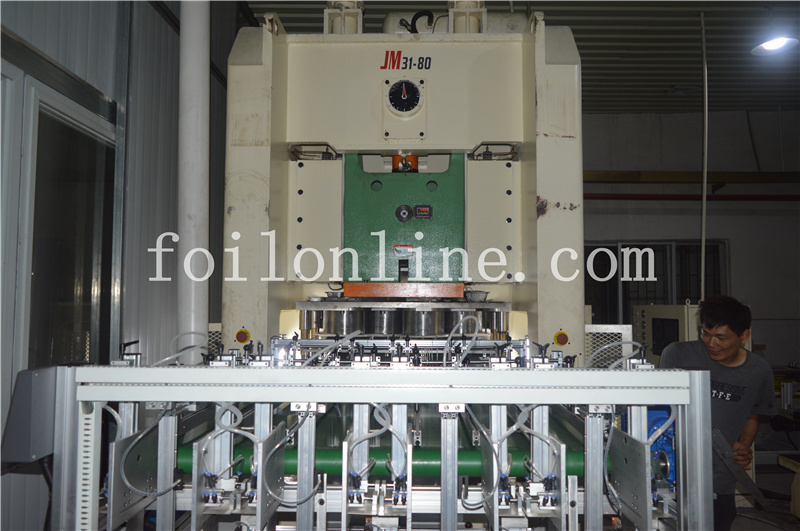

Aluminium Foil Container Stacking Machine

Description

An aluminum foil container stacking machine, also known as an aluminum foil container stacker or stacker machine, is a specialized piece of equipment used to automate the stacking process of aluminum foil containers used for packaging food and other products. It is designed to efficiently and precisely stack the containers in a predetermined configuration for easier transportation, storage, and handling.

The main purpose of an aluminum foil container stacking machine is to eliminate manual labor and increase productivity by automating the stacking process. Here are some key features and functions typically found in an aluminum foil container stacking machine:

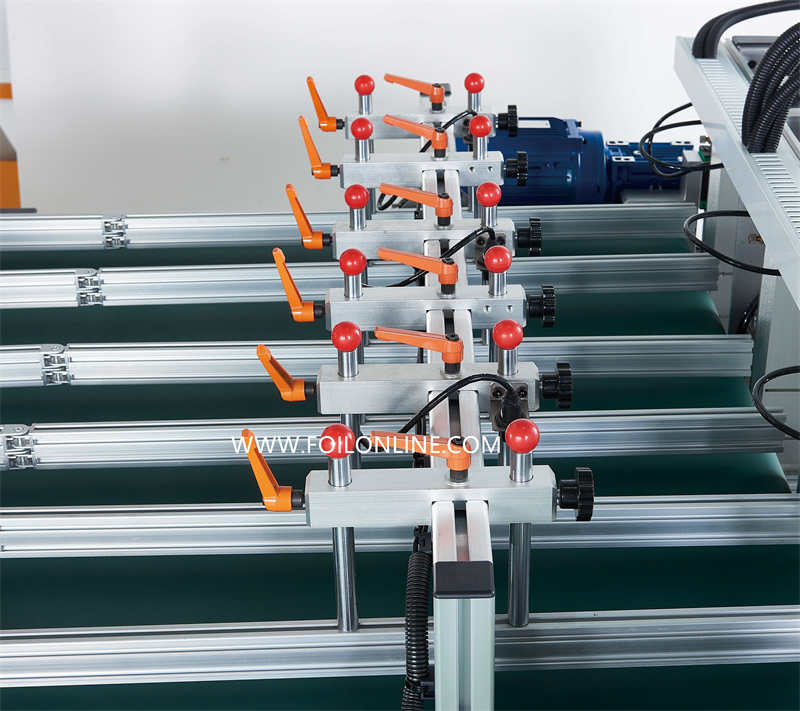

The stacker typically consists of a conveyor system that transports the aluminum foil containers from the production line to the stacking area. The containers are then arranged in a predetermined pattern or configuration, such as a stack or a pallet. The stacker uses robotic arms or mechanical mechanisms to lift and place the containers in the desired arrangement.

Features

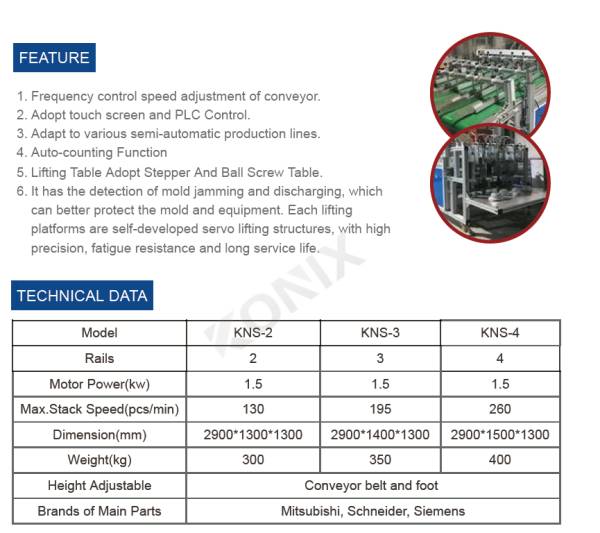

Aluminium Foil Container Stacking Machine commanded by a Programmable Logic Controller (PLC) offers several advantages for labor-saving and production efficiency. Here are the advantages highlighted based on your description:

- Labor Saving: By automating the stacking process, the stacker eliminates the need for manual labor to stack trays and containers. This reduces the physical strain on workers and allows them to focus on other tasks, improving overall productivity.

- Production Efficiency: The stacker ensures consistent and precise stacking of trays and containers, which leads to improved production efficiency. It can stack the items at a faster rate compared to manual stacking, resulting in higher output and reduced production time.

- Handling Different Dimensions: The stacker is designed to handle trays and containers of various dimensions. It can accommodate different sizes, shapes, and configurations, making it versatile and adaptable to diverse packaging requirements.

- Easy Operation and Adjustment: The operative panel connected to the PLC provides a user-friendly interface for controlling the stacker. Operators can easily operate and adjust the machine based on customized requirements, such as stacking patterns, stacking heights, and stacking configurations. This flexibility allows for quick setup and changeover between different product types.

- Customization: The stacker can be customized to meet specific stacking requirements. Whether it’s stacking in columns, rows, or any other desired configuration, the machine can be programmed accordingly. This adaptability ensures that the stacker can cater to the unique needs of different products and packaging.

An aluminum foil container stacking machine offers significant advantages in terms of labor savings, production efficiency, and precise stacking. It helps to streamline operations, increase productivity, and ensure the integrity of the packaged products during storage and transportation.