How Are Aluminum Foil Container-Making Machines Driving Southeast Asia’s Industrial Boom?

Introduction

In the global market, aluminum foil container making machines have carved out a significant niche due to their role in producing essential packaging solutions. These machines are instrumental in creating containers that offer convenience, durability, and hygiene for a variety of consumer goods. As Southeast Asia emerges as a formidable force in the manufacturing sector, the adoption of these advanced manufacturing technologies is accelerating the region’s industrial growth. This article explores the various facets of aluminum foil container making machines in Southeast Asia, highlighting their impact, the demand drivers, the key players involved, the challenges faced, sustainability considerations, and the broader economic impacts.

What Drives the Demand for Aluminum Foil Containers in Southeast Asia?

The demand for aluminum foil containers in Southeast Asia is propelled by a rapidly growing consumer market. With an increasing population and a rising middle class, the region’s appetite for convenient and safe packaging solutions is expanding. Urbanization and economic development are critical factors contributing to this surge in demand.

Urban centers in Southeast Asia are burgeoning, leading to a lifestyle shift towards ready-to-eat and takeaway meals. Aluminum foil containers are preferred due to their ability to maintain food quality and safety. Furthermore, the economic boom in countries like Vietnam, Indonesia, and the Philippines has resulted in higher disposable incomes, allowing consumers to spend more on packaged food and beverages, thereby driving up the demand for aluminum foil containers.

Another contributing factor to the rising demand is the increasing awareness and concern for food safety and hygiene. Aluminum foil containers are known for their excellent barrier properties, protecting food from contamination, moisture, and oxygen. This makes them an ideal choice for packaging perishable items and ensuring that the food remains fresh and safe for consumption. The hospitality and catering industries also heavily rely on these containers for their operations, further boosting demand.

How Are Aluminum Foil Container Machines Transforming Local Industries?

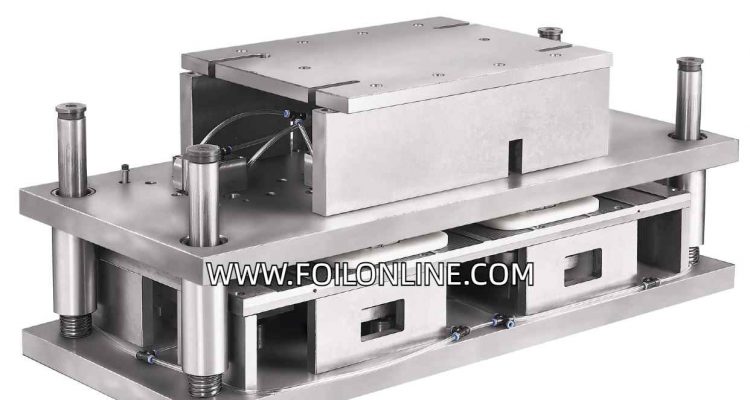

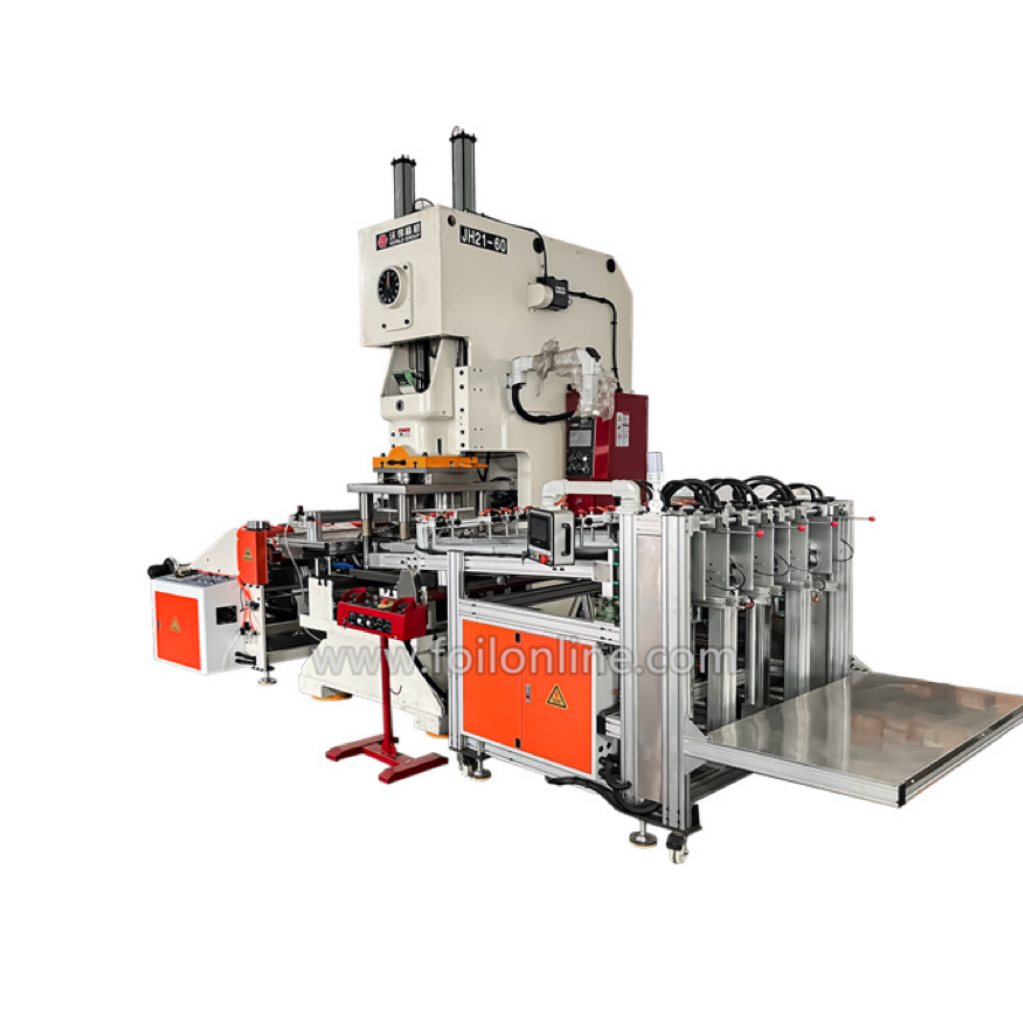

The advent of sophisticated aluminum foil container making machines has revolutionized local industries in Southeast Asia. These machines incorporate cutting-edge technology, enhancing production efficiency and product quality. Automation and precision engineering have enabled manufacturers to meet the growing consumer demands while maintaining cost-effectiveness.

Technological advancements in these machines have significantly boosted local businesses. High-speed production capabilities, coupled with reduced downtime and maintenance, allow manufacturers to scale up operations swiftly. Moreover, the ability to produce containers of various shapes and sizes caters to diverse market needs, from food packaging to pharmaceutical and industrial applications. This versatility is crucial for businesses looking to expand their product offerings and market reach.

Local industries benefit from the increased production capacity and efficiency that these machines provide. Small and medium-sized enterprises (SMEs) in particular have been able to enhance their competitiveness by adopting these technologies. The ability to produce high-quality containers at a lower cost enables these businesses to compete with larger manufacturers and tap into new markets. Additionally, the reduction in manual labor and the automation of production processes contribute to improved workplace safety and reduced operational costs.

Who Are the Major Players in the Southeast Asian Market?

Several key manufacturers and businesses in Southeast Asia are at the forefront of adopting aluminum foil container making machines. Prominent players include local firms like Thong Guan Industries in Malaysia and international corporations such as Reynolds Group Holdings, which have established a strong presence in the region.

Collaborations between local and international firms are also noteworthy. These partnerships facilitate the transfer of technology and expertise, enabling local manufacturers to leverage advanced production techniques. For instance, joint ventures and strategic alliances with companies from China and Europe have helped Southeast Asian manufacturers enhance their production capabilities and product quality.

Additionally, governments in the region are actively supporting the growth of this industry through favorable policies and incentives. Initiatives aimed at attracting foreign investment, improving infrastructure, and fostering innovation are creating a conducive environment for the growth of the aluminum foil container manufacturing sector. This support from the public sector further strengthens the position of key players and encourages new entrants into the market.

What Challenges Do Manufacturers Face in This Region?

Despite the promising growth, manufacturers in Southeast Asia face several challenges. Logistical issues, such as inadequate infrastructure and transportation networks, can hinder the efficient distribution of raw materials and finished products. Additionally, technical barriers, including a lack of skilled labor and access to advanced technologies, pose significant obstacles.

The economic landscape also presents challenges. Fluctuating commodity prices and currency exchange rates can impact the cost of production and profitability. Furthermore, the regulatory environment in Southeast Asia varies across countries, with differing standards and compliance requirements. Navigating these regulations can be complex and time-consuming, requiring manufacturers to stay abreast of changing policies and ensure adherence to local laws.

Another significant challenge is the competition from other regions with well-established manufacturing industries. Countries like China and India, with their extensive industrial bases and lower production costs, present stiff competition to Southeast Asian manufacturers. To overcome this, manufacturers in the region need to continuously innovate and improve their processes to maintain a competitive edge. Investing in research and development, adopting best practices, and leveraging technology are essential strategies to address these challenges and sustain growth.

How Sustainable Are Aluminum Foil Container Making Machines?

Sustainability is a crucial consideration in the production and use of aluminum foil containers. The environmental impact of aluminum foil production, particularly in terms of energy consumption and carbon emissions, is a significant concern. However, innovations in recycling and sustainability practices are mitigating these effects.

Aluminum is infinitely recyclable, and recycling it requires only 5% of the energy used to produce new aluminum. This inherent recyclability makes aluminum foil containers a more sustainable packaging solution compared to alternatives like plastic. Advances in recycling technologies and the implementation of circular economy principles are further enhancing the sustainability of aluminum foil container production.

Manufacturers are increasingly adopting eco-friendly practices, such as using recycled aluminum in production and investing in energy-efficient machinery. These efforts not only reduce the environmental footprint but also align with the growing consumer demand for sustainable products. Furthermore, initiatives aimed at reducing waste and promoting recycling at the consumer level are contributing to a more sustainable lifecycle for aluminum foil containers.

The adoption of green technologies and practices also presents economic benefits. By reducing energy consumption and waste, manufacturers can lower production costs and improve profitability. Additionally, meeting environmental standards and certifications can open up new markets and attract environmentally conscious consumers, further driving business growth.

What Are the Economic Impacts of Adopting Advanced Manufacturing Technologies?

The adoption of advanced manufacturing technologies, including aluminum foil container making machines, has profound economic implications for Southeast Asia. These technologies drive productivity and efficiency, leading to cost savings and increased competitiveness in the global market.

The broader economic benefits include job creation and GDP growth. As manufacturers expand operations and enhance production capabilities, they generate employment opportunities across various sectors, from machine operation to logistics and sales. This job creation is vital for the region’s economic development, contributing to poverty alleviation and improved living standards.

Furthermore, the growth of the aluminum foil container industry stimulates other sectors, such as transportation, retail, and services, creating a multiplier effect on the economy. The increased demand for raw materials, machinery, and related services supports a wide range of businesses, fostering overall economic growth.

The impact on local economies is particularly significant in rural and semi-urban areas, where the establishment of manufacturing facilities can drive infrastructure development and economic activity. Improved roads, utilities, and other essential services resulting from industrial growth enhance the quality of life for local communities. Additionally, the increase in employment opportunities and income levels contributes to social stability and development.

Conclusion

Aluminum foil container making machines play a pivotal role in Southeast Asia’s industrial surge. The growing consumer market, driven by urbanization and economic development, fuels the demand for aluminum foil containers. Technological advancements in these machines are transforming local industries, enhancing production efficiency and product quality.

Key players, including local and international firms, are driving the industry’s growth through strategic collaborations. However, manufacturers face challenges such as logistical, technical, and economic barriers, as well as navigating the regulatory environment. Sustainability remains a crucial focus, with efforts to reduce the environmental impact of aluminum foil production through recycling and eco-friendly practices.

The economic impacts of adopting advanced manufacturing technologies are substantial, contributing to job creation and GDP growth. As Southeast Asia continues to embrace these technologies, the future outlook for the aluminum foil container industry is promising, poised to further elevate the region’s industrial capabilities and economic prosperity. With continued innovation and strategic investments, Southeast Asia is well-positioned to become a global leader in the aluminum foil container manufacturing sector.

Contact Us to Learn More!

Are you interested in how aluminum foil container making machines can revolutionize your business? Want to explore the latest advancements and industry insights? Contact us today to get more information and discover how you can leverage this technology for your success.

Contact Us Now and take the next step towards enhancing your manufacturing capabilities!