Explore Applications of Aluminum Foil Container Molds

Have you ever stopped to think about how those shiny, durable aluminum containers in your kitchen come to life? From the trays you use to bake lasagna to the takeaway boxes from your favorite restaurant, these handy containers start with a fascinating piece of technology—the aluminum foil container mold. These molds are the unsung heroes of the food packaging world, quietly shaping the products we use every day. But their applications stretch far beyond what meets the eye.

In this article, we’ll explore the versatile uses of these molds, what they’re made of, how they’re structured, and why they’re so essential. By the end, you’ll see why businesses everywhere rely on them to create innovative and practical solutions for everyday life.

What Are Aluminum Foil Container Molds?

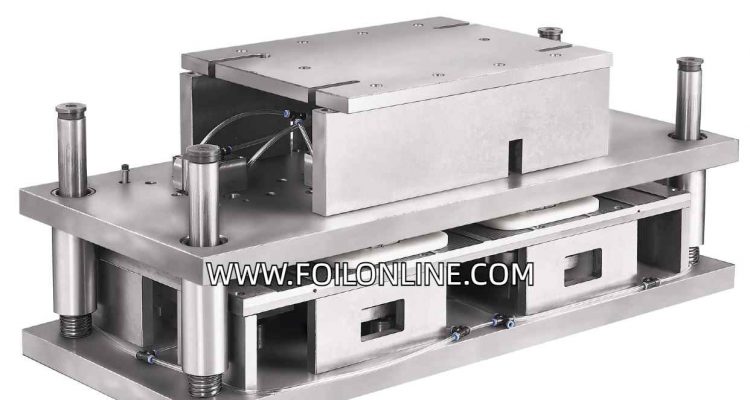

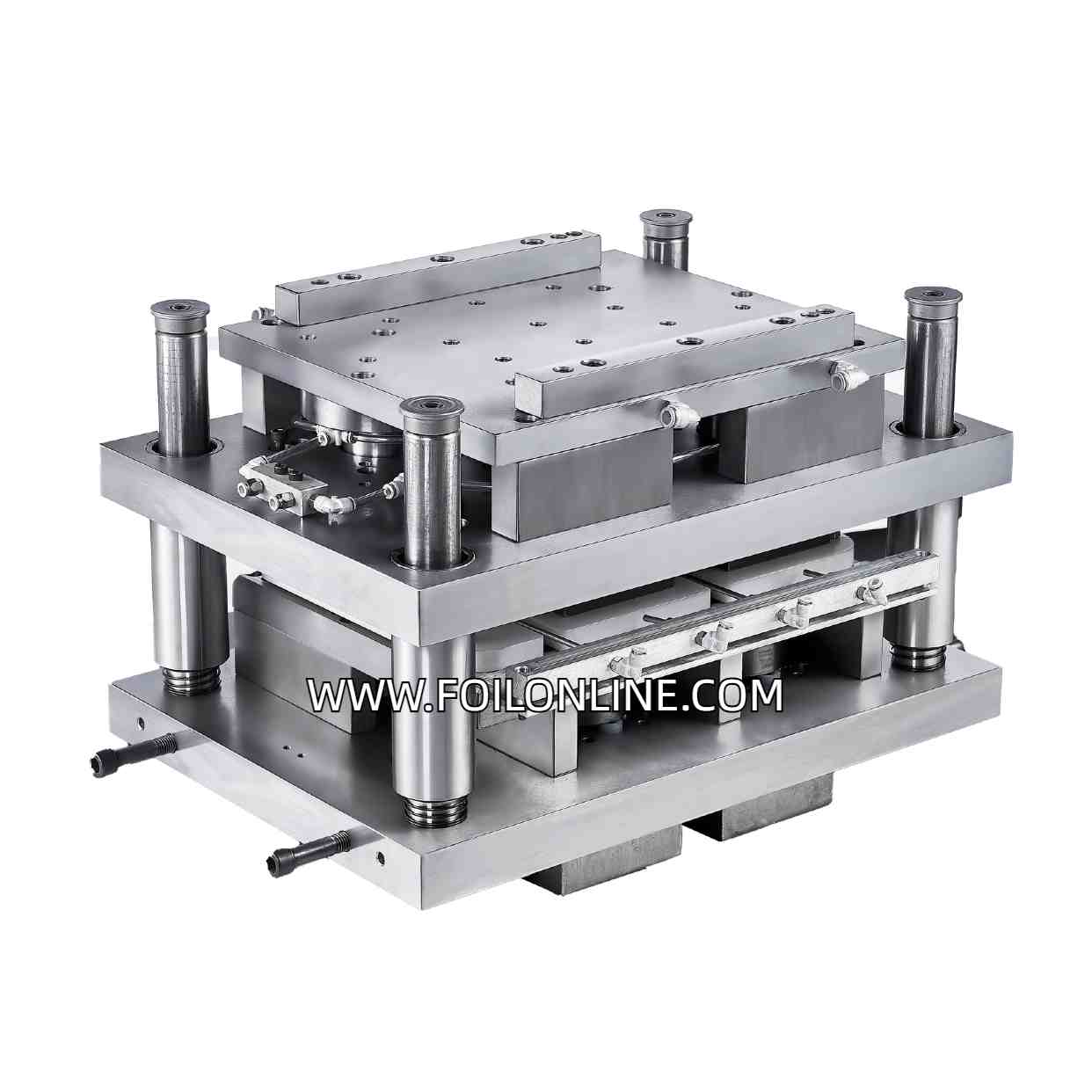

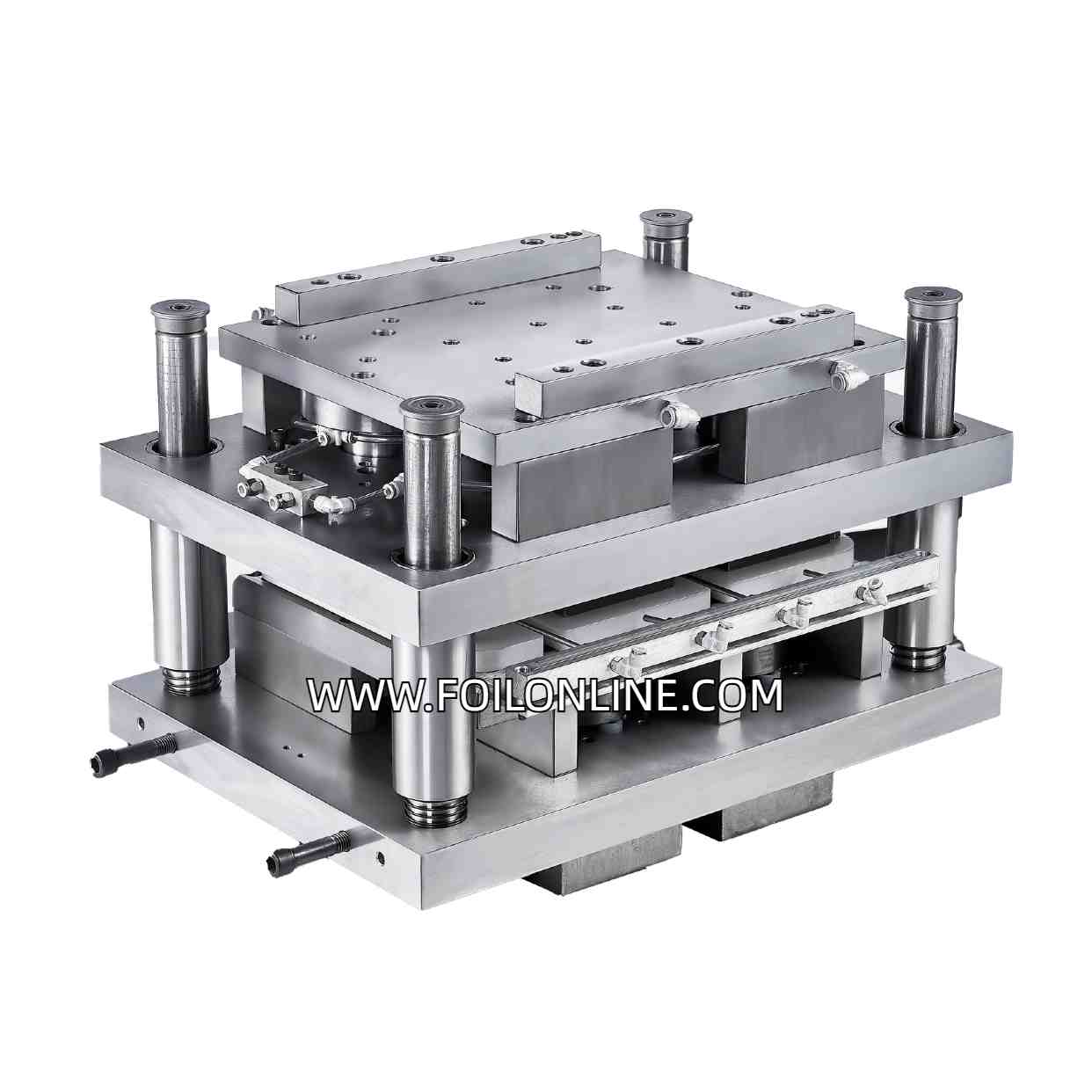

At their core, premium aluminum foil container molds are specialized tools used to shape aluminum foil into containers of various sizes and shapes. These molds are the backbone of mass production in the packaging world. Whether it’s a tray for baking or a box for storing leftovers, the mold ensures that each container is uniform and perfectly shaped.

Why is this important? Uniformity is key in industries like catering and food packaging, where containers need to stack neatly and seal securely. These molds streamline production, allowing manufacturers to produce thousands of containers efficiently. For businesses, this reliability translates into reduced waste, cost savings, and high-quality packaging that consumers trust.

The role of these molds isn’t limited to mass production. They also allow for the customization of containers, enabling businesses to meet specific needs or design unique products. With the right mold, you can create containers in various sizes, styles, and even with embossed designs for branding purposes.

What Are They Made Of?

Durability and precision are vital when it comes to aluminum foil molds. That’s why these tools are typically made from hardened steel, such as DC53 or Cr12MoV. These materials undergo heat treatments to make them resistant to wear and tear, ensuring they can handle the repeated stress of production.

The design is just as important as the material. These molds are crafted with exact measurements to ensure that every container they produce is identical. Many molds are designed to perform multiple tasks, such as cutting, shaping, and even embossing, all in one step. This saves time and boosts efficiency.

High-quality materials like heat-treated steel ensure that molds last for years without degradation. This reliability is essential for industries that depend on consistent production schedules. Investing in durable materials also reduces maintenance and replacement costs, making it a smart choice for manufacturers.

The Highlight: Application Scenarios

Now, let’s dive into the star of the show—the many ways high-quality aluminum foil molds are used. Their versatility makes them invaluable across industries.

Food Packaging

Picture the last time you ordered a meal to-go. Chances are, it came in an aluminum foil container that was sturdy enough to hold piping hot food and sleek enough to prevent leaks. These containers, shaped by aluminum molds, are perfect for food delivery and takeaway services.

Restaurants and catering companies also depend on them for storing and serving meals. The containers’ ability to preserve freshness while being lightweight and disposable makes them a top choice in the food industry. In grocery stores, pre-packed meals are often sold in these containers, offering convenience for busy customers.

Baking and Confectionery

Bakeries and pastry shops have another story to tell. Aluminum containers shaped by these molds are ideal for baking cakes, pies, and bread. Because they conduct heat evenly, they help ensure baked goods come out perfectly every time. Plus, their ability to withstand high oven temperatures means they’re as reliable as they are convenient.

In addition to traditional baking, these containers are popular for specialty treats like muffins and tarts. Some molds are designed specifically for creating smaller portions, which makes them ideal for selling individual servings at bakeries or coffee shops.

Airline Catering

Ever been on a plane and enjoyed a neatly packed meal? Those small, lightweight trays are also products of high-performance aluminum molds. Airline catering depends on these containers because they’re easy to stack, seal, and dispose of—exactly what’s needed in a fast-paced, high-volume environment.

The reliability of these containers is crucial in airline services, where food safety and freshness are non-negotiable. The molds used to create these trays ensure that they are leak-proof and sturdy, even when filled with hot or cold meals.

Outdoor Events and Parties

For outdoor barbecues or large gatherings, aluminum foil containers are a lifesaver. They’re perfect for serving and storing food in casual settings where cleanup needs to be quick and easy. These containers, made possible by precision molds, combine convenience with practicality.

Large-scale events like food festivals and fairs also rely on these containers for serving meals to hundreds or even thousands of attendees. Their lightweight nature makes them easy to transport, while their strength ensures they can handle heavy portions of food.

Industrial and Specialized Uses

Beyond food, aluminum containers are used in various industries to store chemicals, organize tools, or even for medical packaging. Their lightweight yet durable nature makes them ideal for multiple purposes. In laboratories, for instance, aluminum trays are often used for experiments or sample storage, thanks to their resistance to corrosion.

Why They Stand Out: Performance Benefits

The magic of these molds doesn’t stop with their applications. The containers they produce have a host of benefits that make them an obvious choice for businesses and consumers alike.

Preservation of Quality

Aluminum foil containers act as barriers against moisture, light, and air, ensuring that food stays fresh for longer. Whether it’s a hot meal or a frozen dessert, these containers lock in flavor and texture.

In addition to food preservation, aluminum’s reflective surface protects contents from harmful light exposure, which is particularly useful for sensitive items like dairy products or cosmetics.

Durability

Despite their lightweight build, aluminum containers are surprisingly strong. They can hold everything from delicate pastries to hefty roasts without bending or breaking. This strength makes them ideal for transporting food over long distances without risk of spillage.

Heat Resistance

These containers are designed to withstand extreme temperatures. Whether they’re used in ovens, on grills, or in freezers, they maintain their shape and functionality. This makes them an all-in-one solution for cooking, storing, and reheating meals.

Eco-Friendliness

In today’s eco-conscious world, aluminum’s recyclability is a major advantage. Containers made with aluminum can be recycled indefinitely, reducing waste and supporting sustainability. Choosing aluminum containers over plastic or Styrofoam helps businesses reduce their environmental impact while still meeting their packaging needs.

Configurations and Customization

No two businesses are exactly alike, and aluminum foil container molds reflect that flexibility. They come in a variety of configurations to meet specific needs.

Single or Multi-Cavity Molds

For businesses that need high production volumes, multi-cavity molds are the way to go. These molds can produce several containers at once, speeding up the manufacturing process.

Rim Styles

Different uses call for different rim styles. From G-style rims that allow easy sealing to folded edges for better stacking, molds can create a variety of options tailored to specific industries.

Customization

Customization is where these molds truly shine. They can be designed to produce containers in unique shapes, sizes, or even with embossed logos. This not only meets functional requirements but also helps businesses stand out in a competitive market.

Adding custom logos or patterns to the containers not only improves branding but also communicates quality to consumers. For example, bakeries or restaurants can emboss their brand logo onto the containers, creating a memorable experience for their customers.

Why Quality Matters

Investing in high-quality aluminum molds isn’t just about convenience—it’s about ensuring your final product meets the highest standards. Poorly designed molds can result in containers that are weak or inconsistent in shape, which can harm a brand’s reputation.

Companies like FoilOnline prioritize precision and durability in their molds, helping clients create containers that exceed expectations. Choosing reliable molds is a long-term investment in efficiency and customer satisfaction.

Conclusion

From food packaging to airline catering and beyond, aluminum foil container molds are an essential part of modern life. They make it possible to create containers that are durable, heat-resistant, and eco-friendly—all while meeting the unique needs of various industries.

Whether you’re in the food business, a bakery, or another field entirely, these molds are a game-changer. If you’re looking for reliable and customizable options, explore the top-quality molds available at FoilOnline.

Ready to elevate your packaging solutions? Explore our premium range of aluminum foil container molds designed to meet your exact needs. Whether you’re in food service, catering, or manufacturing, we have the perfect solution for you.

Visit us at FoilOnline to browse our products, or get in touch with our team for expert advice and custom options. Have questions or need assistance? Contact us today! Our team is ready to help you find the ideal molds to streamline your operations and boost your business. Don’t wait—let’s create something exceptional together!

Take your packaging to the next level—one perfectly shaped container at a time!