Aluminium Foil Container Moulds from Concept to Production Advantages

Introduction

Nowadays, packaging, in general, has gained immense importance in everyday life because it preserves food fresh, clean, and safe, hence easy to handle. In every field of commerce, in foodstuffs, the food catering industries, among the most usable containers are those prepared from aluminium foil because they are strong yet excessively lightweight and recyclable.

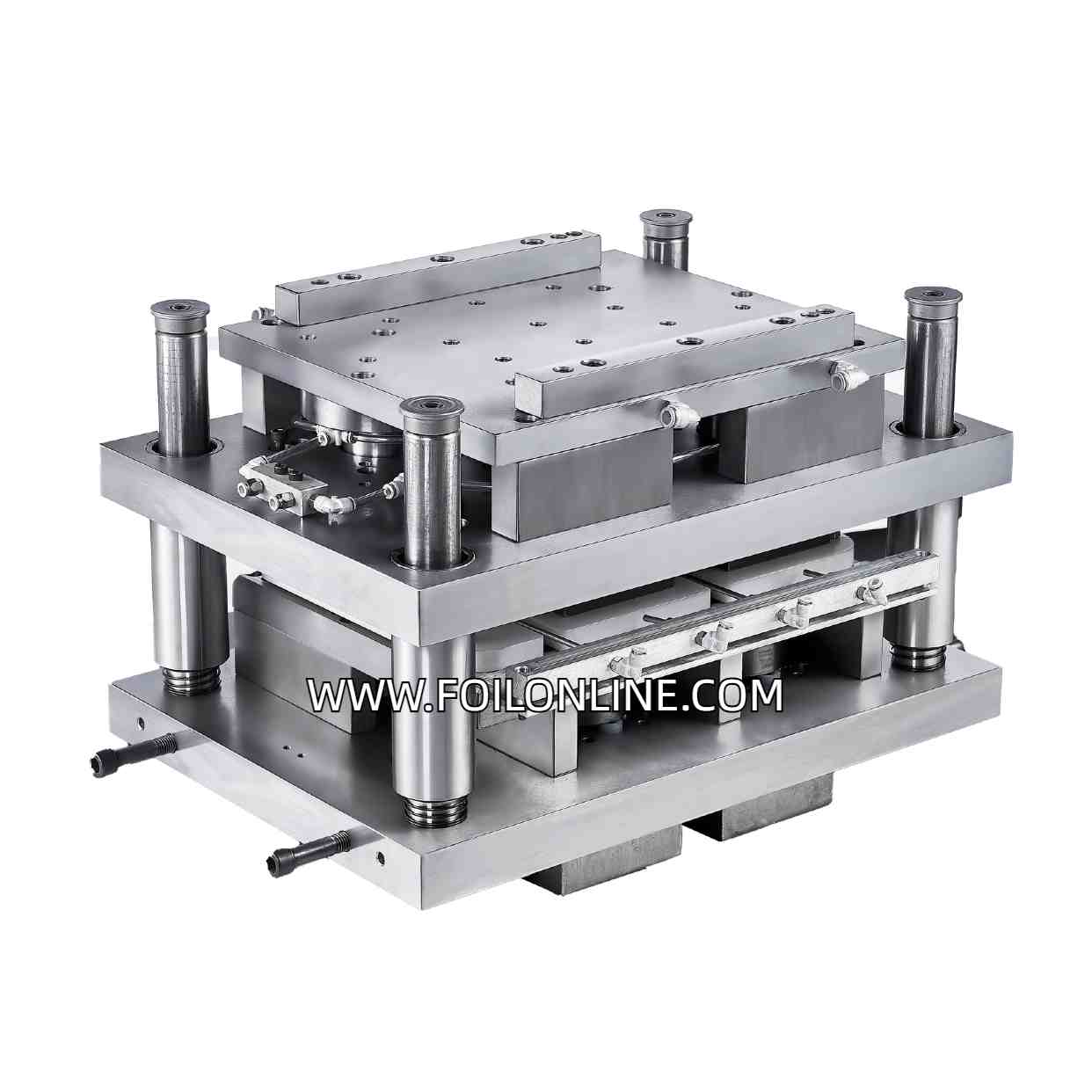

To obtain such containers, manufacturers require precise tools in the name of moulds, called ‘aluminium foil container moulds,’ which shape the foil into different forms. FoilOnline is a leading company in aluminium foil container mould manufacturing. Known for our quality and dedication to innovation, we design and produce moulds that help businesses create reliable, high-quality packaging.

In this article, we’ll take you through the process of how these moulds are made—from the initial concept to the finished product. You will also learn about many advantages of the moulds of the aluminium foil containers and why choosing a trustworthy partner, such as FoilOnline, means much.

What is an Aluminium Foil Container Mould?

An advanced aluminium foil container mould is a device that gives thin aluminium foil shapes into containers. These containers are quite common in the food industry for takeout meals, baked goods, and prepared foods because they are lightweight, high-strength, and easily recyclable. The mould gives each container its shape, size, and thickness to fit all food shapes and endure various temperatures.

The applications of aluminium foil containers are not limited to food services but also extend to other industries like pharmaceutical and cosmetic ones. They provide non-toxic, safe storage of products, keeping them fresh at the same time. At FoilOnline, we specialise in the creation of custom moulds for each type of client’s need.

The moulds in our possession assist corporations in the production of containers, meeting the quality and strength standards that enable each container to demonstrate its performance as expected under real conditions.

The Process: From Concept to Production of Aluminium Foil Container Moulds

Creating an aluminium foil container mould involves several important steps. Each step is carefully planned to ensure the moulds are accurate, durable, and meet high standards. Here’s how the process works, from the initial concept to the final product.

Step 1: Conceptual Design

It includes the design phase at the beginning. During this process, FoilOnline works directly with the client to understand its needs-for instance, what kind of shape, size, or thickness the container should be. Our design team develops a model using special computer software called CAD, which is short for Computer-Aided Design.

It is what the final container design will look like. With FoilOnline, each client’s needs are met according to unique requirements; hence, the mould perfectly fits the desired container style.

Step 2: Material Selection

Following the approval of the design, the selection of mould materials would be the next appropriate step. The container is made of aluminium, which is light, flexible, and easy to recycle. In the same instance, the mould will require hard and durable enough to support many usages; therefore, a high-grade metal like hardened steel would typically be applied to make it.

This steel is durable and can handle such pressures and wear from creating large containers. In this way, by using quality materials, FoilOnline assures the mould will last longer, producing containers with consistent quality.

Step 3: Mould Manufacturing

Once the design and materials have been finalised, mould manufacturing begins. It is the most crucial stage of mould production, where several highly accurate engineering methods are employed, including Computer Numerical Control (CNC) milling and Electrical Discharge Machining (EDM). Both manufacturing techniques use computer-controlled machines that carve the steel exactly into the desired mould form.

CNC milling allows the machine to carve out minute details in the mould, while EDM does the necessary fine, smooth-surfaced mouldings. All these techniques are to ensure the mould is highly accurate; this is critical in ensuring that the containers produced will be able to meet the set standards within the industry. At FoilOnline, we use the latest technology to ensure every mould is excellently handcrafted to the highest precision.

Step 4: Quality Testing

Before the mould goes into full production, it undergoes a series of quality tests, one of them being trial runs. These are small runs in which a few containers are produced from the mould. The produced samples will be checked against the design specifications for size, shape, and other aspects, such as durability.

It is further tested for strength so that it does not break down quickly or easily wear out with high-volume production stress. At FoilOnline, we pride ourselves on quality and make sure each mould meets high standards before dispatch to the client.

Step 5: Maintenance and Optimization

Even when moulds are in action, maintenance does not stop. It means cleaning, wear and tear consideration, and, generally speaking, all adjustments that are needed. If properly maintained, moulds can make top-quality containers continuously for a much longer period. FoilOnline also desires to offer tips and guidelines to the clients for maintaining the moulds, which helps reduce any possible downtime and ensures a defect-free production process.

Through this painstaking process, FoilOnline can produce moulds that are accurate, hard-wearing, and ready for whatever the industry requires in high-quality aluminium foil containers. Each phase of the design, up to maintenance, has been handled with precision so that our clients receive reliable moulds, which will help them move toward success in their production.

Advantages of Aluminium Foil Container Moulds for Production

One of the many benefits of using a high-quality aluminium foil container mould as a packaging material is that it guarantees to provide strength, reliability, and environmental friendliness. The following are some of the major advantages.

1. Sustainability and Environmental Benefits

The material aluminium is highly sustainable due to the fact that it can be recycled constantly without loss of any quality, hence being very eco-friendly. Using aluminium foil containers reduces waste and encourages a greener society in which humans can live.

Most importantly, FoilOnline is committed to a green manner with its use of premium-grade aluminium to make its container products according to the environmental standards of over 100 countries worldwide.

2. Cost Efficiency

Cost efficiency is one of the major advantages one could get with aluminium foil container moulds. Aluminium containers are light in weight; hence, they require less material for their production since the thinness does not affect their quality. In that respect, the cost of manufacturing these products will be reduced.

Also, the moulds are designed for high-rate production; this enables firms to generate a large number of containers within a short period of time. By using premium-quality moulds provided by FoilOnline, enterprises have an opportunity to cut costs without deterioration of quality.

3. Versatility in Application

It is due to its flexibility that aluminium foil containers have been put to use within an array of industries. They come in different shapes, sizes, and thicknesses, making them perfect for a variety of uses-food packaging to storage containers for other products, among others. FoilOnline offers custom moulds, which can be altered to meet specific requirements and give businesses the needed versatility.

4. Durability and Performance

Aluminium foil containers are strong and resistant to punctures; hence, it is more suitable for holding and protecting the content during transportation. They will also resist high and low temperatures, making them safe for freezing and baking. Moulds at Foil Online are designed to produce hard-wearing and reliable containers that always work well under various conditions.

At the same time, these advantages make top-quality aluminium foil container moulds ideal for those industries that stand for quality, sustainability, and efficiency.

How FoilOnline Stands Out in the Aluminium Foil Container Mould Industry

FoilOnline, through the years, has gained expertise, sustainability, and customer support in the aluminium foil container mould industry. With our vast experience, we know what it takes to make moulds that work perfectly in any field, whether the food industry or pharmaceutical.

One of the key strengths is environmental friendliness: we contribute to waste reduction by using recyclable materials, taking your packaging requirements into consideration with efficient modes of production.

Moreover, FoilOnline provides the best customer support. Our personnel are always ready to answer all questions, give recommendations for maintenance, and provide technical support to the clients. We also have competitive pricing so our clients receive the best quality at a fair price.

These strengths make FoilOnline the go-to choice for businesses in search of high-quality and eco-friendly moulds of aluminium foil containers. In fact, our foremost concentration on quality, sustainability, and customer satisfaction is what sets us apart.

Conclusion

Aluminium foil container moulds play an essential role in creating strong, lightweight, and recyclable containers that many industries depend on. These moulds allow for efficient, high-quality production, making it possible to create containers that are reliable and safe for packaging food, pharmaceuticals, and more.

From the careful design process to the final product, each mould is crafted to meet exacting standards, ensuring durability and consistency in every container it helps produce. At FoilOnline, we remain firmly dedicated to offering top-profile moulds through our interests in advanced technology, quality materials, and individualised solutions for each customer.

Our commitment to environmental sustainability and reliable customer support sets us apart from others in the industry. With years of experience and a commitment to excellence at FoilOnline, our customers get products they can trust to meet their production goals while strengthening eco-friendly practices.

Call to Action

Ready to elevate your packaging production? FoilOnline provides top-quality, custom aluminium foil container moulds designed for durability and efficiency. Contact us today to discuss your needs and get the perfect mould solution for your business. Get in touch with FoilOnline now!