What is an aluminum foil container automatic feeder? What is its role?

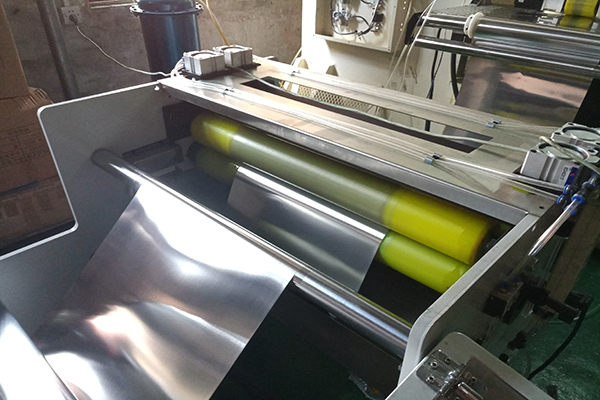

The automatic feeder is an auxiliary aluminum foil container equipment suitable for automatic feeding of aluminum foil coil materials, and the feeding precision is ensured by digital control. It can assist the automatic production of aluminum foil machine punching machines, lathes and other machine tools, and solve the problems of laborious, time-consuming, safe and efficient manual feeding.

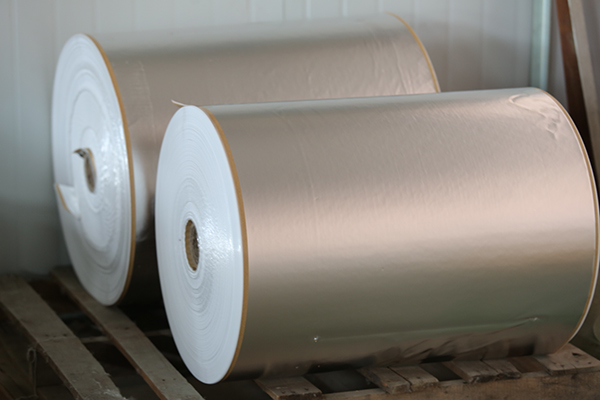

Aluminum Foil Rolls

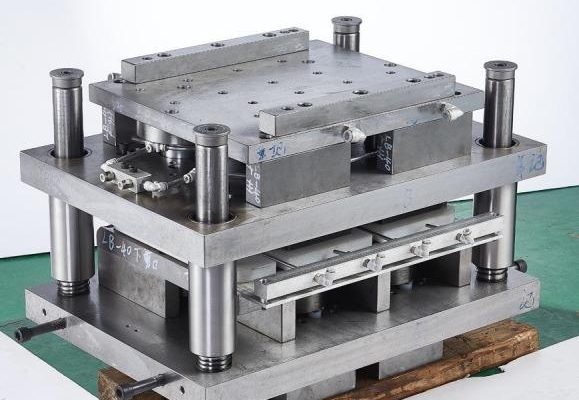

In today’s society, more and more industries will adopt mechanized transportation. This automatic feeder has high precision, is environmentally friendly, saves time, and greatly reduces labor intensity. Really achieve low cost and high return. the value of. The feeder in the feeder is a new type of product independently developed and developed by technicians according to market demand. It can be adapted to the numerical control products used by small and medium-sized enterprises. The feeder is a pneumatic clamp clamped with a dovetail groove to clamp the steel plate and clamp. Easy to move, reduce the bending deformation of the data, reduce the dead zone of the processing, select the high-torque servo motor with high torque, the driver with long life and high precision, the precision ball screw, the high-performance linear rolling guide, which can meet the various requirements of the stamping process. It is especially suitable for product parts with high processing precision requirements, and overcomes the use defects such as large punch vibration, unstable precision and short mold life.

Aluminum Foil Decoiler

The aluminum foil container automatic feeder refers to the automatic operation according to the specified requirements and the established procedures. The person only needs to determine the control requirements and procedures, and does not need to directly operate the feeding mechanism. That is, the mechanism that automatically transfers items from one location to another, during which the process can be automatically and accurately completed without human intervention. Generally, there are a detecting device, a feeding device, and the like. It is mainly used for the transportation of semi-products of various materials and industrial products, and can also be used to automate production in the next process.