The Advantages of Aluminium Container Lid-Making Machine

Introduction

Aluminum containers are a common sight in the food packaging industry today. They are widely used because they are lightweight, strong, and easy to recycle. However, producing these containers, especially their lids, requires specialized machinery. It is where aluminum container lid-making machines come in. These machines help manufacturers produce large quantities of high-quality lids efficiently.

As the demand for packaged food grows, so does the need for reliable packaging solutions. Aluminum container lids are important in keeping food fresh, safe, and easy to transport. In this blog, we’ll explore the many benefits of aluminum container lid-making machines, including how they save time, reduce costs, and improve production quality.

What is an Aluminum Container Lid-Making Machine?

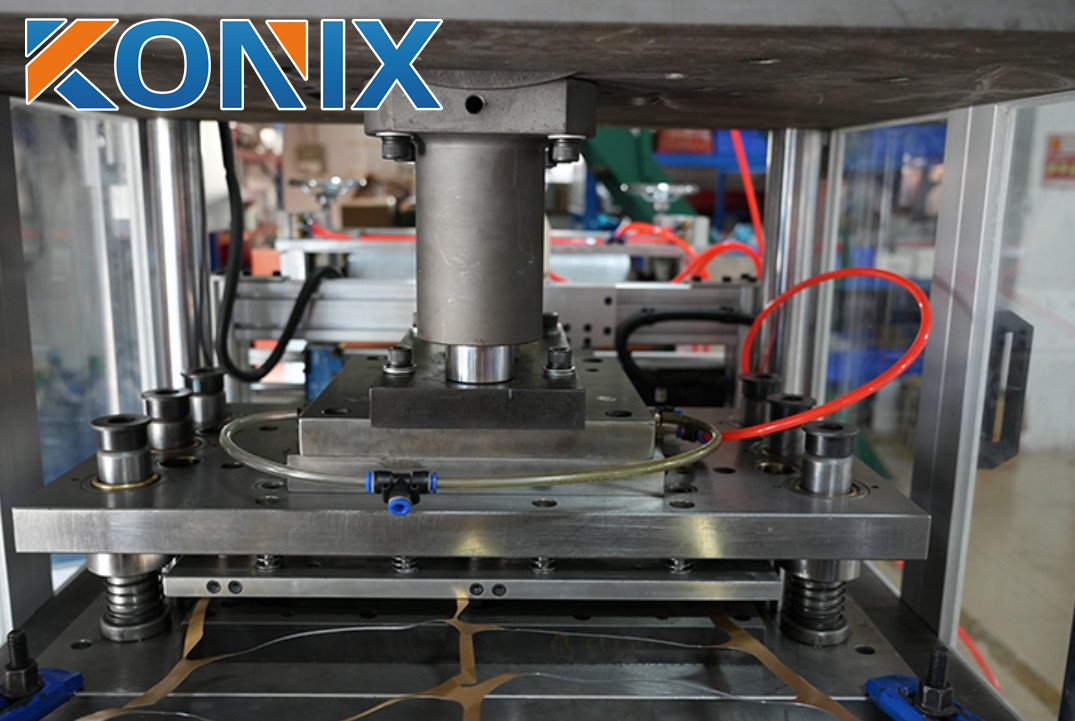

An aluminum container lid-making machine is a specialized tool used to produce lids for aluminum food containers. These lids are essential for sealing and protecting food, making them a key part of food packaging. The machine takes large rolls of aluminum foil, feeds them into the system, and then forms and punches out lids of different shapes and sizes. It can make lids for various types of containers, from small, individual food trays to large catering containers.

The process starts with feeding the aluminum into the machine, where a mold shapes it. After that, the machine punches the lid into the desired shape. These machines often come with automatic stacking and waste management systems to ensure the process runs smoothly and without waste.

These features make production quick and efficient, helping manufacturers meet the high demand for aluminum lids.

Key Benefits of Aluminum Container Lid-Making Machines

Aluminum container lid-making machines offer many benefits to businesses that produce food packaging. These machines help manufacturers improve their production in several ways, including increased efficiency, cost savings, and better product quality. Let’s look at some of the key benefits.

Increased Production Efficiency

One of the biggest advantages of aluminum lid-making machines is their ability to produce large quantities of lids quickly. Some machines can make up to 540 lids per minute! This high speed allows companies to meet the growing demand for food packaging without needing extra workers. In addition to speed, these machines can work continuously, meaning there’s less downtime, which helps increase production output.

Cost-Effectiveness

These machines can also help businesses save money. Since they can produce lids in bulk, the cost of making each lid becomes lower. Automated machines also reduce the need for a lot of workers, helping companies save on labor costs. Plus, advanced features like scrap recycling systems ensure that no material goes to waste, which can further cut down costs.

Customization and Flexibility

Another great feature of aluminum lid-making machines is their ability to produce different types of lids. These machines can adjusted to create lids in various sizes, shapes, and designs. Whether you need a small, embossed lid or a large, smooth lid, the machine can handle it all. This flexibility allows manufacturers to meet the specific needs of their customers.

Improved Product Quality

These machines are equipped with automated quality control systems. They can detect and remove lids that do not meet the required standards, ensuring only the best products reach the customers. The precision of the molds also ensures that each lid fits perfectly on its container, which is important for keeping food fresh and secure.

By using aluminum container lid-making machines, businesses can increase efficiency, reduce costs, and produce high-quality products, making them a valuable investment.

Features that Make Your Aluminum Container Lid-Making Machines Stand Out

Your premium aluminum container lid-making machines offer some unique features that make them a great choice for manufacturers. These features not only improve efficiency but also ensure that the machines are easy to use, reliable, and highly productive.

Advanced Automation Systems

Your machines are equipped with advanced automation systems, such as a PLC (Programmable Logic Controller) control system and servo-driven technology. These systems allow the machines to operate smoothly and accurately, even at high speeds. Operators can control the machines through an easy-to-use touch-screen interface, making adjustments simple and reducing the chance of errors.

This high level of automation helps speed up production and ensures that every lid is made with precision.

High-Speed, Accurate Production

One of the key selling points of your machines is their ability to produce up to 540 lids per minute using multi-cavity molds. These molds allow the machine to punch out several lids at once, making the process faster and more efficient. This high speed, combined with the machine’s accuracy, ensures that manufacturers can meet large orders on time without sacrificing quality.

Durable and User-Friendly Design

Your machines are built to last, with high-strength welding structures that ensure durability even in demanding production environments. They are also designed with user-friendliness in mind, featuring automated feeding systems and stacking mechanisms that reduce manual labor. This combination of durability and ease of use makes your machines a reliable investment for long-term production needs.

By combining advanced technology, speed, accuracy, and a user-friendly design, your aluminum container lid-making machines stand out from the competition and offer manufacturers a powerful tool for improving their packaging processes.

How Aluminum Lid-Making Machines Improve Efficiency in Manufacturing

Aluminum lid-making machines are designed to make the manufacturing process faster, smoother, and more efficient. Here’s how these machines help companies boost their productivity while reducing waste and errors.

Minimizing Human Error

One of the main ways high-performance aluminum lid-making machines improve efficiency is by reducing the chances of human error. Because the machines are automated, they handle everything from feeding the aluminum to punching and stacking the lids. This automation ensures that each lid is made with the same precision and quality, leaving little room for mistakes that can occur with manual labor.

Streamlined Workflow

These machines are built with integrated systems that make the whole process much more organized. For example, they often come with automatic feeding and stacking systems, meaning the aluminum foil is fed into the machine without needing constant manual attention.

The lids are then automatically stacked, making the process faster and easier for the workers. This streamlined workflow not only saves time but also helps companies produce more lids in less time.

Faster Turnaround Time

Another great feature is the ability of the machines to switch between different molds quickly. It allows manufacturers to produce lids of different sizes and shapes without needing long setup times. As a result, businesses can meet various customer demands faster and more efficiently, which is essential for companies that work with different types of containers.

By automating key steps, reducing the need for manual work, and allowing quick mold changes, aluminum lid-making machines play a big role in improving efficiency for manufacturers. It makes them an excellent investment for companies looking to boost their production output.

Technical Insights for Existing Users: Maintenance and Optimization Tips

Aluminum container lid-making machines require regular maintenance to keep them running efficiently and ensure a long service life. Here are some simple tips for maintaining and optimizing your machine:

Regular Maintenance

Regularly checking the key parts of the machine, like the mold, feeder, and punching system, is crucial. These components can wear out over time, so cleaning and inspecting them often will prevent breakdowns and ensure smooth operation. Lubricating moving parts also helps reduce friction and extend the machine’s lifespan.

Optimizing Production Output

It’s important to set the right feeding speed and adjust the mold based on the type of lid being produced To get the best performance from the machine. Keeping an eye on the sensors and control systems can help you detect any potential issues early and make adjustments to ensure consistent quality. Proper setup and fine-tuning can also help improve the machine’s speed without compromising on accuracy.

Training Staff

Make sure the operators are well-trained to use the machine efficiently. It includes knowing how to operate the touch-screen control system, adjust settings, and troubleshoot common issues. A well-trained team can spot problems early and make quick fixes, which keeps the machine running smoothly and reduces downtime.

Following these tips will help you get the most out of your aluminum container lid-making machine, keeping production efficient and trouble-free.

Conclusion

In conclusion, aluminum container lid-making machines offer numerous benefits for manufacturers in the food packaging industry. They boost production efficiency, reduce costs, and allow for flexible, high-quality lid production. With advanced automation systems, durable designs, and built-in quality control, these machines are a smart investment for businesses looking to stay competitive. By regularly maintaining and optimizing your machines, you can ensure they run smoothly for years, providing consistent, high-quality results.

As demand for sustainable and efficient packaging grows, aluminum lid-making machines are helping businesses meet these needs. Investing in such technology will not only improve your production processes but also help you deliver better products to your customers.

Ready to upgrade your production? Explore our range of aluminum container lid-making machines today!

Call to Action

Ready to boost your packaging production? Invest in our high-efficiency aluminum container lid-making machines to improve quality and cut costs. Visit FoilOnline to learn more and get in touch for a quote: Contact US. Let’s help you grow your business today!