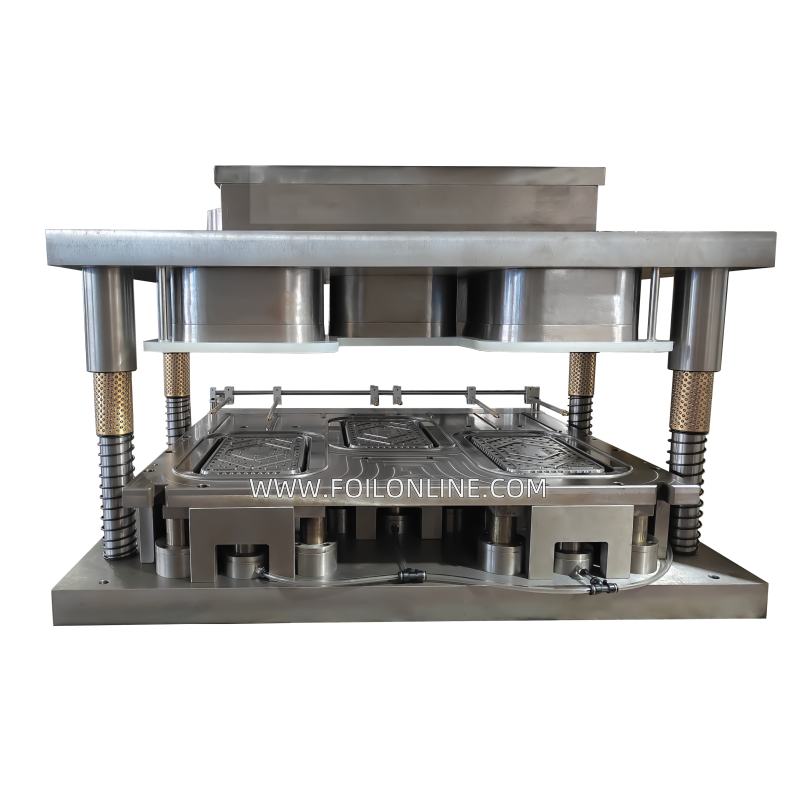

3 Cavities Rectangle Shape Aluminium Foil Container Mould

Rim/Curl: IVC, Full Curl, Reverse Curl

Delivery time: 60 Days

Brand: KONIX

Place of Origin: Guangzhou, China

3 Cavities Rectangle Shape Aluminium Foil Container Mould

Introduction

The 3 Cavities Rectangle Shape Aluminium Foil Container Mould is specifically engineered for the food industry, facilitating the efficient and precise production of aluminum foil containers, including trays, pans, and dishes. This specialized mould enhances versatility in food packaging and serving, making it a valuable asset for businesses aiming to improve their operational efficiency.

Design and Functionality

This mould is designed to shape aluminum foil into various container forms, optimizing production for high-demand environments with a capacity of around 150 pieces per minute, depending on the number of cavities used. With over 13 years of R&D experience, KONIX ensures each mould adheres to the highest quality standards, allowing them to supply top-notch molds globally.

Key Features

- Gas Compression Principle: The mould utilizes gas compression and rebound to achieve high precision and stability during production.

- Precision Manufacturing: Crafted with a processing accuracy of 0.005mm, the mould employs advanced techniques like heat treatment and WEDM-LS.

- Integrated Processing: It efficiently handles multiple manufacturing stages—cutting, stretching, forming, curling, and finishing—accommodating different sides like G side, L side, or IVC folding side.

- Longevity: Designed to last between 10 million and 100 million cycles (excluding wear parts), critical components such as shears and guide pillars are built for durability.

- Material and Technology: Constructed from high-grade materials like DC53, and CR12MOV, the mould undergoes processes such as quenching, vacuum heat treatment, and deep cold treatment to enhance durability. Precision guide posts and bushes, slow wire cutting, and surface grinding further ensure exceptional craftsmanship.

- Speed and Size: It operates at 45-50 cycles per minute, with sizes customizable based on container specifications and cavity numbers.

KONIX prioritizes strong customer relationships by providing reliable tools with extended lifespans and excellent service, including the delivery of spare parts within two weeks. This commitment fosters trust and satisfaction among clients in the aluminum foil container manufacturing sector.

Sales Service

KONIX offers comprehensive support services:

- Overseas Machinery Service: Engineers are available for timely assistance and maintenance abroad.

- Internship and Worker Training: They provide training to enhance worker skills in operating molds and machines effectively.

- Technical Assistance: Continuous technical support is offered throughout installation, testing, and maintenance phases.

The team is also equipped to make modifications to size, capacity, functionality, or automation features of the mould, ensuring it aligns with your production goals.

Conclusion

The 3 Cavities Rectangle Shape Aluminium Foil Container Mould not only enhances productivity and streamlines operations but also offers reliability and durability for continuous performance. Designed for minimal downtime, it helps manufacturers consistently meet production targets. Using imported mold steel from Japan, these molds ensure stable use for up to ten years.

While the mould is a crucial component, the aluminum foil container manufacturing process involves additional steps such as foil feeding, punching, and stacking. Overall, manufacturers typically invest in customized molds tailored to specific shapes, sizes, and production capacities, making this mould an essential investment for optimizing operations.