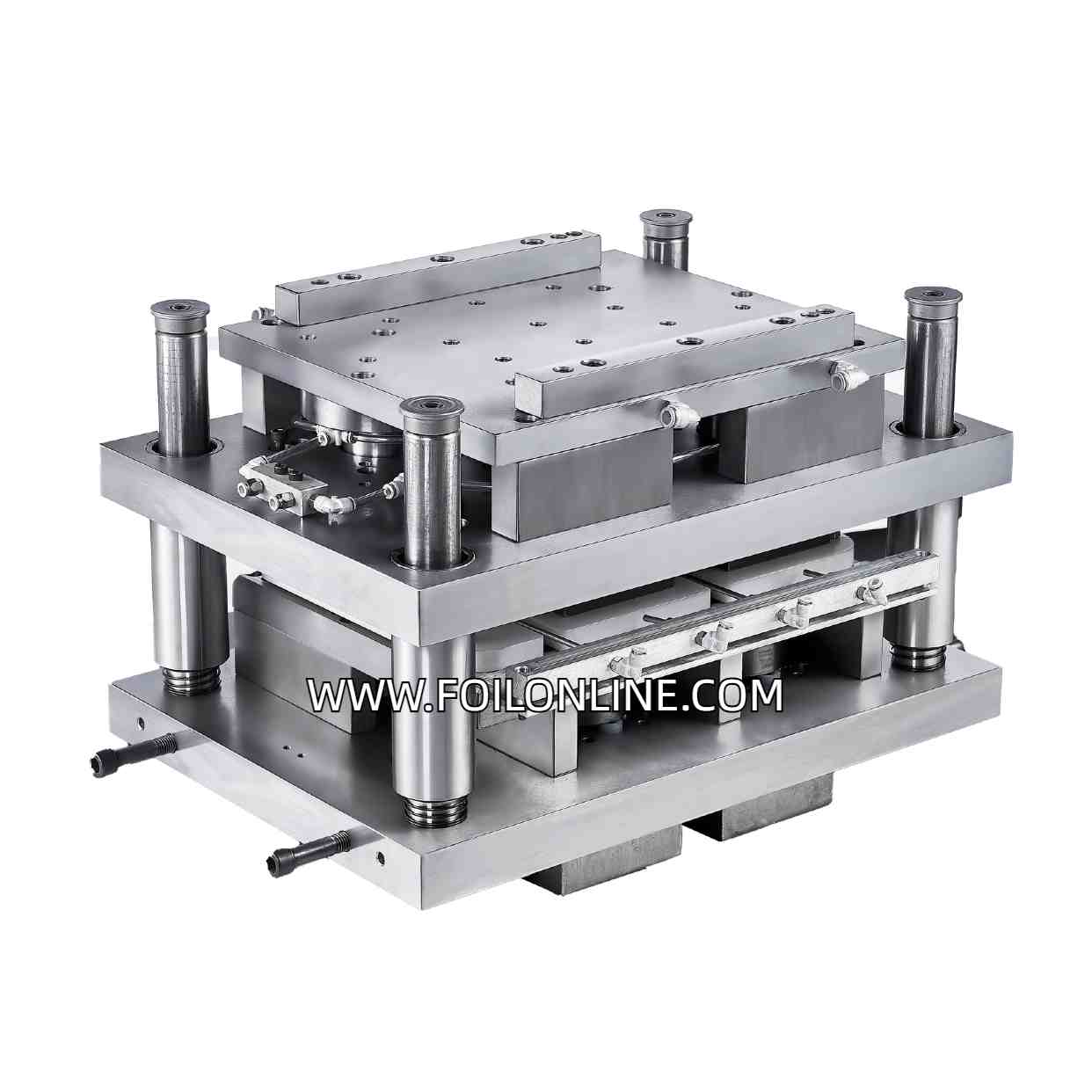

Four Cavities Aluminium Foil Container Mould

Specification: muti cavity

Container size: On requirement

Brand: KONIX

Place of Origin: Guangzhou, China

Driven Type: Pneumatic

Four Cavities Aluminium Foil Container Mould

INTRODUCTION

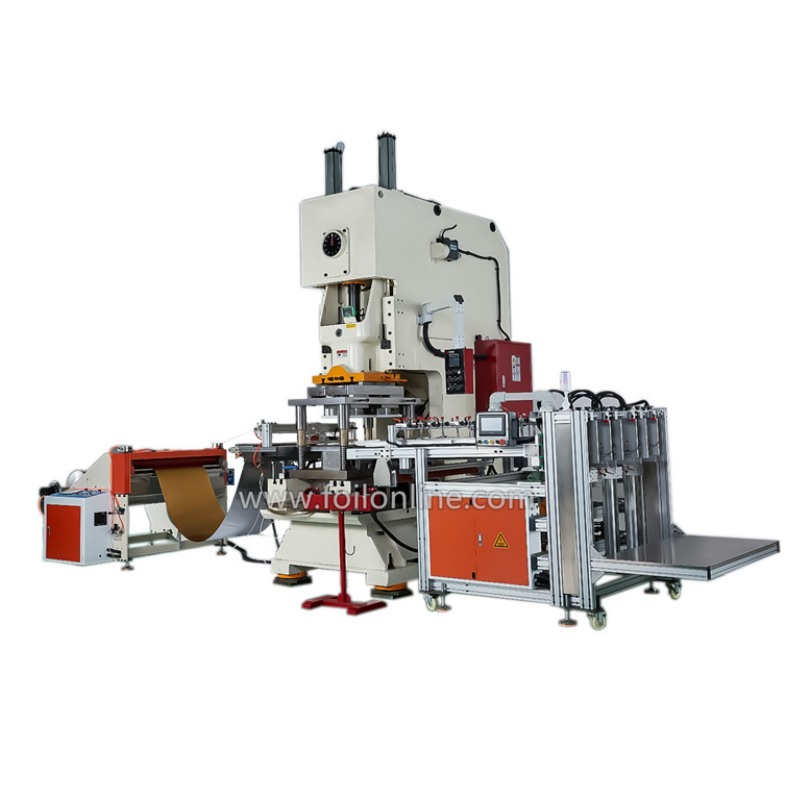

The Four Cavities Aluminium Foil Container Mould is engineered specifically for the food industry, enabling efficient and precise production of aluminum foil containers like trays, pans, and dishes.

- Design and Functionality: This specialized mould shapes aluminum foil into various container forms, enhancing versatility for food packaging and serving.

- Production Efficiency: With a production capacity ranging from 180 to 200 pieces per minute, depending on the number of cavities used, it optimizes output for high-demand environments.

- Expertise: KONIX brings over 13 years of R&D experience to the table, ensuring that each mould is crafted with the highest quality standards. Their commitment to excellence has allowed them to supply top-notch moulds globally.

This combination of advanced design, high production capacity, and years of expertise makes the Four Cavities Aluminium Foil Container Mould a smart investment for businesses looking to enhance their packaging efficiency and quality.

FEATURE

- Gas Compression Principle: Utilizing gas compression and rebound, the mould achieves high precision and stability during the manufacturing process.

- Precision Manufacturing: With a processing accuracy of 0.005mm, this mould is crafted using top-notch heat treatment and WEDM-LS techniques, ensuring exceptional quality.

- Integrated Processing: The mould handles multiple stages—cutting, stretching, forming, curling, and finishing—efficiently in one go, accommodating various sides like G side, L side, or IVC folding side.

- Longevity: Designed for a service life of 10 million to 100 million cycles (excluding wear parts), with critical components like shears and guide pillars built to endure.

- Material and Technology: Constructed from high-grade materials such as 45 carbon steel, DC53, and CR12MOV, the mould undergoes quenching, vacuum heat treatment, and deep cold treatment to enhance durability. It incorporates precision guide posts and bushes, slow wire cutting, and precision surface grinding for exceptional craftsmanship.

- Speed and Size: Operating at speeds of 45-60 cycles per minute, the mould’s size can be customized based on container specifications and cavity numbers.

KONIX prioritizes customer relationships, offering reliable tools with extended lifespans and a commitment to service, including spare part delivery within two weeks. This dedication further solidifies trust and satisfaction among clients in the aluminum foil container manufacturing industry.

SALES SERVICE

- Overseas machinery service: Our team of engineers is available to provide service and support for machinery overseas, ensuring timely assistance and maintenance.

- Internship and worker training: We offer internship services and can assist in training your workers to operate molds and machines effectively, enhancing their skills.

- Technical assistance: We provide constant technical assistance to support users throughout the installation phases, testing processes, and continuous maintenance of the machines.

Whether you require modifications to size, capacity, functionality, or automation features of aluminum foil container mould 2 Cavity, our team of experts works closely with you to design and manufacture a machine that precisely fits your production goals.

Our production line and Four Cavities Aluminium Foil Container Mould enhance productivity and streamline operations, but it also offers reliability. Built to last, our machines are durable and designed for continuous performance, minimizing downtime, and allowing you to meet your production targets consistently. Our molds use mold steel imported from Japan to ensure stable use for up to ten years

Manufacturers of aluminum foil containers typically invest in customized molds based on their specific requirements. These molds are designed to meet the desired container shapes, sizes, and production capacities.

It’s worth noting that while Four Cavities Aluminium Foil Container Mould IS widely used, the actual manufacturing process involves several other steps, including aluminum foil feeding, punching, and stacking, among others. The molds play a crucial role in shaping and forming the containers accurately and efficiently.