China Aluminum Foil Container Stacking Machine

Brand : KONIX

Product origin: Guangzhou, China

Delivery time: 30 Days

Supply capacity: 300 Set/Year

STABLE /EFFICIENT /EASY TO OPERATE

- 1~6 Lanes Available

- Customization to Order

- Leading Automation System

China Aluminum Foil Container Stacking Machine

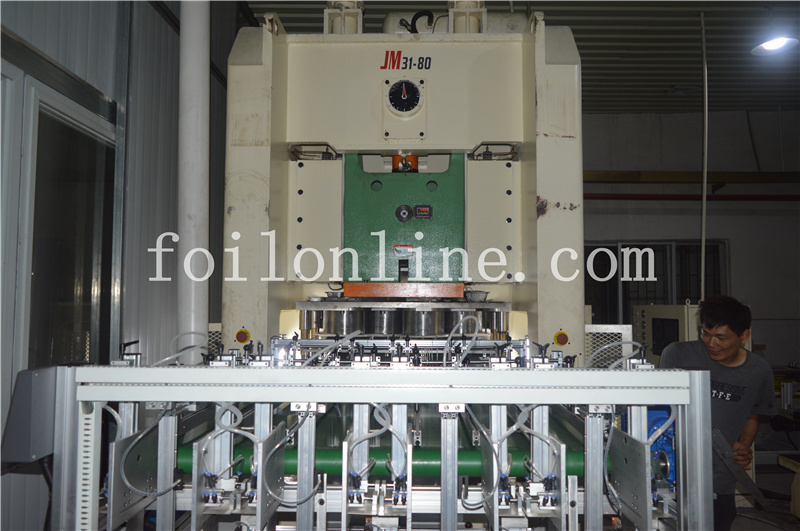

KONIX Aluminum Foil Container Stacking Machine is used to automatically collect containers blown out of the mold, greatly saving labor and improving efficiency.

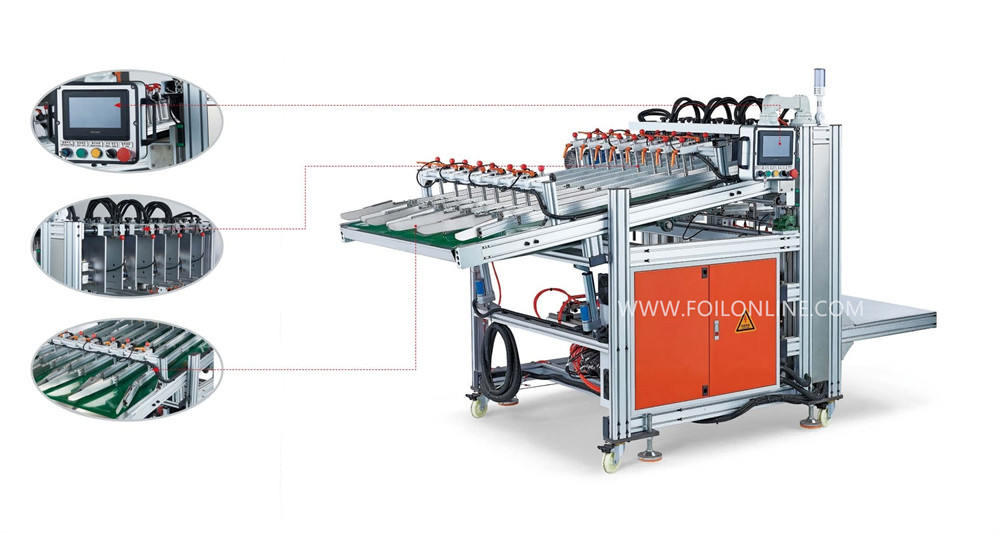

Control system

Setting system: INOVANCE/SIEMENS

Inverter: INOVANCE/MISTUBISHI

Power supply: MEAN WELL

Other electrical parts: Schneider

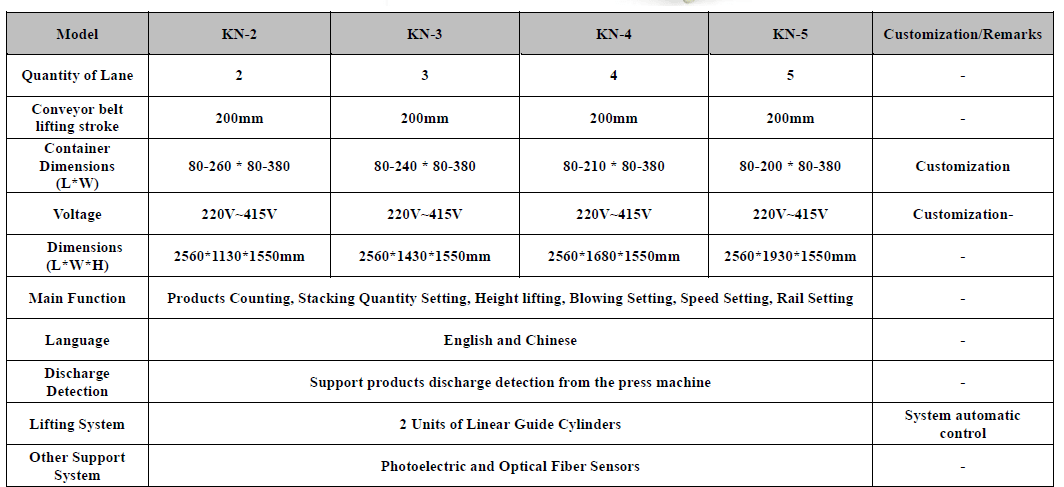

The Aluminum Foil Container Stacking Machine provides a variety of models to choose from, from one track to six tracks, matching according to the number of cavities of the mold.

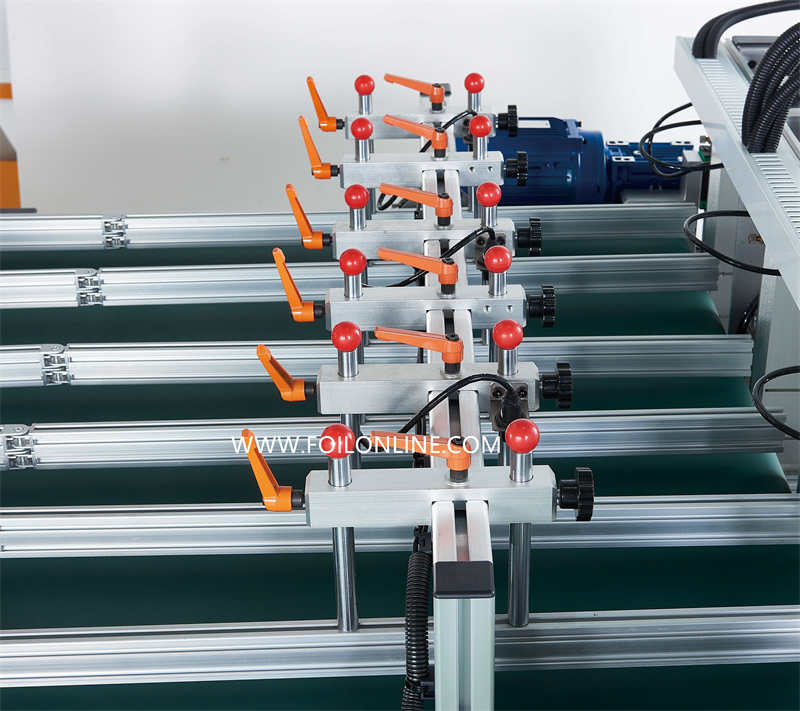

- Structure

It adopts aluminum profile frame structure, with beautiful and solid appearance, suitable for the collection of various types and sizes of aluminum foil containers.

- Operation

Through the movable touch system, users can easily set the collection quantity, control the conveyor belt speed, the height of the collection platform, count the collection quantity, etc. By adjusting the precise tools on the collection machine, the container collection size can be easily adjusted

- Electrical

Cooperate with INOVANCE, a leading global provider of industrial automation. Use the complete control system, including display, PLC, inverter and motor, etc. The experience of Aluminum Foil Container Stacking Machine is extremely stable and smooth.

Creating an Aluminum Foil Container Stacking Machine would involve a system that can efficiently pick up trays, stack them neatly, and possibly even count them. The machine could use sensors and robotic arms to identify and stack the trays accurately. Think of a conveyor belt system with robotic arms that can stack the trays in a precise manner one on top of the other. This could greatly increase efficiency in packaging processes for industries that use aluminum foil trays.