Maximize Profitability in Recycling with Advanced Scrap Balers

- 1.Maximize Profitability in Recycling with Advanced Scrap Balers

Introduction

In an era where environmental consciousness is paramount, recycling has become a crucial aspect of waste management and resource conservation. As the recycling industry continues to evolve, the introduction of advanced technology has significantly enhanced its profitability. Among the most impactful advancements are scrap balers, which play a vital role in the efficient processing of recyclable materials. This article delves into the importance of scrap balers, their economic benefits, and how they contribute to maximizing profitability in recycling.

What Are Scrap Balers and How Do They Work?

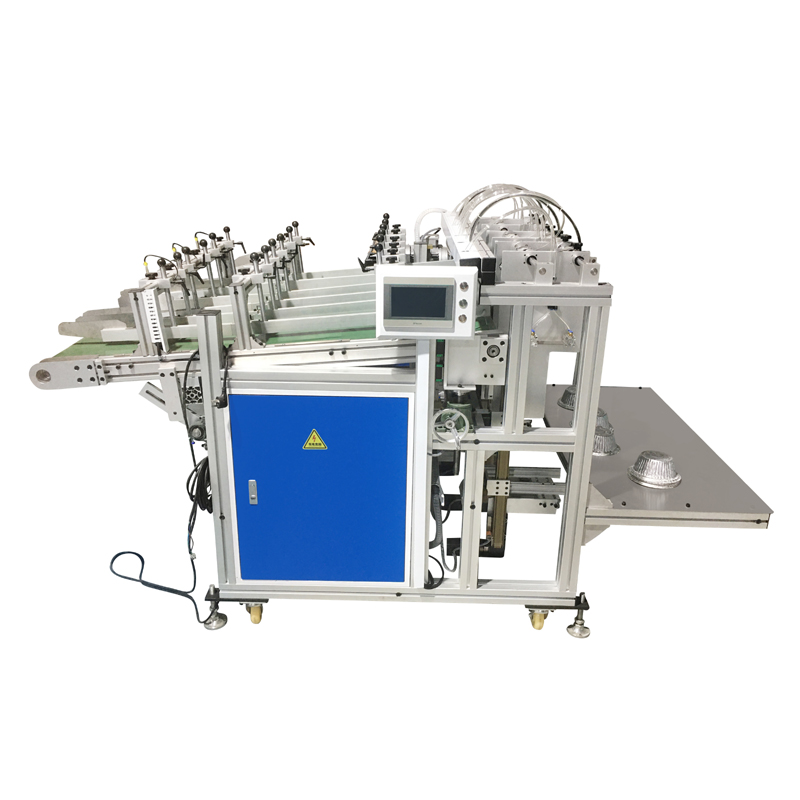

Scrap balers are machines designed to compress recyclable materials such as paper, cardboard, plastics, and metals into compact bales. This process not only reduces the volume of waste but also simplifies handling, storage, and transportation. Balers operate through a combination of hydraulic or pneumatic systems that apply pressure to the recyclable materials, forming dense, manageable bales. These machines come in various sizes and configurations, including vertical and horizontal balers, to cater to different recycling needs.

Vertical balers are typically used for smaller volumes and are ideal for facilities with limited space. They require manual loading but are efficient for businesses that generate smaller amounts of recyclable materials. Horizontal balers, on the other hand, are suited for high-volume operations. They can be automated to handle continuous feeding of materials, making them ideal for large recycling centers and industrial applications.

The Economic Benefits of Using Advanced Scrap Balers

Investing in advanced scrap balers can significantly reduce operational costs and increase revenue for recycling facilities. High-quality balers are engineered for efficiency and durability, ensuring that they can handle large volumes of material with minimal downtime. By producing uniform and dense bales, these machines optimize storage space and reduce transportation costs, as more material can be transported in fewer trips.

Moreover, advanced balers often feature automation capabilities, such as automated feeding and ejection systems, which streamline the baling process and minimize the need for manual intervention. This level of efficiency translates to lower energy consumption and reduced wear and tear on the equipment, ultimately leading to cost savings over time.

How Do Advanced Balers Reduce Labor Costs?

One of the most significant advantages of advanced scrap balers is their ability to reduce labor costs. Traditional baling methods often require extensive manual labor to sort, feed, and operate the baling machines. In contrast, modern balers equipped with automation and smart technology can perform these tasks with minimal human input. Automated balers can sort and compress materials continuously, allowing operators to focus on other critical aspects of the recycling process.

Additionally, the enhanced efficiency and speed of advanced balers mean that fewer workers are needed to achieve the same output levels. This reduction in labor requirements not only cuts down on payroll expenses but also minimizes the risk of workplace injuries associated with manual handling of heavy materials.

Increasing Recycling Rates with High-Performance Balers

High-performance balers are designed to handle a wide range of recyclable materials, including those that are traditionally difficult to process. This versatility enables recycling facilities to accept and process more types of waste, thereby increasing their recycling rates and material recovery. Advanced balers also produce bales of consistent density and size, which are preferred by recycling mills and processors, ensuring a higher market value for the bales.

Moreover, the reliability and durability of these balers mean that facilities can operate continuously with minimal downtime for maintenance or repairs. This continuous operation is crucial for maximizing throughput and achieving higher recycling rates.

Comparing Traditional vs. Advanced Balers: A Cost-Benefit Analysis

When evaluating the financial implications of investing in advanced balers, it is essential to compare them with traditional balers. While traditional balers may have a lower initial cost, the long-term benefits of advanced balers often outweigh the upfront investment.

Initial Investment and Operational Costs

Advanced balers typically come with a higher price tag due to their sophisticated technology and features. However, these machines are designed for efficiency and durability, resulting in lower operational costs over time. Traditional balers may require more frequent maintenance and repairs, leading to higher long-term expenses.

Efficiency and Productivity

Advanced balers offer superior efficiency and productivity compared to traditional models. Automation and smart technology enable faster processing and reduced manual labor, resulting in higher output levels. This increased productivity translates to more significant revenue potential for recycling facilities.

Labor and Energy Savings

As discussed earlier, advanced balers significantly reduce labor costs through automation and efficiency. Additionally, these machines are designed to be energy-efficient, consuming less power to perform the same tasks as traditional balers. These savings in labor and energy contribute to the overall cost-effectiveness of advanced balers.

Environmental Impact

Advanced balers are more effective at compressing materials into dense bales, reducing the need for transportation and storage space. This efficiency not only lowers operational costs but also minimizes the environmental impact of recycling activities. By reducing the carbon footprint associated with transportation and storage, advanced balers contribute to a more sustainable recycling process.

Implementing Advanced Balers: Steps for Seamless Integration

For businesses looking to upgrade their recycling equipment, implementing advanced balers can be a straightforward process with the right approach. Here are some practical tips and strategies for seamless integration:

1.Assess Your Needs: Evaluate the types and volumes of materials your facility processes to determine the most suitable baler for your needs. Consider factors such as material type, bale size, and throughput requirements.

2.Research and Select the Right Baler: Research different baler models and manufacturers to find a machine that meets your specific requirements. Look for features such as automation, durability, and energy efficiency.

3.Plan for Installation: Ensure that your facility is prepared for the installation of the new baler. This preparation may involve making space adjustments, ensuring proper power supply, and training staff on the new equipment.

4.Train Your Team: Provide comprehensive training for your operators and maintenance personnel to ensure they are familiar with the new baler’s operation and maintenance procedures. Proper training will maximize the efficiency and lifespan of the equipment.

5.Monitor and Optimize: After installation, closely monitor the baler’s performance and make any necessary adjustments to optimize its operation. Regular maintenance and inspections will help keep the machine running smoothly and prevent unexpected downtime.

Maximizing ROI Through Strategic Use of Advanced Balers

Investing in advanced scrap balers is not just about acquiring new equipment; it involves a strategic approach to maximize return on investment (ROI). Here are additional considerations to ensure that businesses fully leverage their advanced balers for profitability:

Regular Maintenance and Upgrades: Regular maintenance is crucial to keep advanced balers operating at peak efficiency. Implementing a preventive maintenance schedule can prevent costly breakdowns and extend the lifespan of the equipment. Additionally, staying informed about technological advancements and upgrading balers when necessary can keep the facility competitive.

Optimizing Material Flow: Efficient material flow is essential for maximizing the productivity of balers. Ensuring that recyclable materials are sorted and fed into the baler promptly can minimize downtime and enhance throughput. Automated conveyor systems and material handlers can further streamline this process.

Leveraging Data and Analytics: Many advanced balers come equipped with sensors and software that provide real-time data on performance metrics. Utilizing this data can help facilities identify bottlenecks, monitor efficiency, and make informed decisions to optimize operations.

Training and Development: Continuous training for employees is vital to maintain high operational standards. Investing in ongoing education for operators and maintenance staff ensures they are up-to-date with the latest best practices and technological advancements.

Exploring New Revenue Streams: Advanced balers can open up new revenue streams by enabling the processing of a wider range of materials. Facilities can explore partnerships with manufacturers and other businesses to recycle specialty materials, creating additional income opportunities.

Conclusion

Investing inadvanced scrap balersoffers numerous economic and operational benefits for recycling facilities. These machines enhance efficiency, reduce labor costs, and increase recycling rates, ultimately maximizing profitability. By carefully selecting and implementing the right baler, businesses can achieve long-term financial gains and contribute to a more sustainable recycling process. As the recycling industry continues to evolve, embracing advanced technology such as scrap balers will be crucial for staying competitive and environmentally responsible.

By strategically integrating advanced balers into their operations, recycling facilities can not only enhance their profitability but also play a significant role in promoting environmental sustainability. The future of recycling lies in leveraging innovative technology to create efficient, cost-effective, and environmentally friendly solutions. Advanced scrap balers are a pivotal part of this future, driving the industry toward greater success and sustainability.

Contact Us for Advanced Scrap Balers Today!

Are you ready to maximize profitability in your recycling operations with advanced scrap balers? At FoilOnline, we offer a wide range of high-quality feeder stacker scrap balers designed to boost efficiency, reduce labor costs, and increase recycling rates. Explore our selection here and take the first step towards a more efficient and profitable recycling process.

For more information or to discuss your specific needs, don’t hesitate to contact us. Our team of experts is ready to assist you in finding the perfect solution for your facility. Reach out today and let us help you transform your recycling operations with our state-of-the-art scrap balers.